15-12-25

Read now: The winter issue of K>MOBIL is here!

Challenges? We focus on clear strategies and innovation and continue to drive our global growth forward with investments in modern technologies and the development of sustainable products.

You can read exactly what this means in the latest issue of K>MOBIL.

The industry faces numerous challenges: strained supply chains, rising raw material and energy prices, protectionist measures, and growing demands for sustainability and digitalization.

The KIRCHHOFF Group is responding with clear strategies, sustainable technologies, and flexible procurement channels. For example, we are improving our carbon footprint with new materials for battery-electric vehicles. KIRCHHOFF Ecotec has created a new digital competence center for innovative AI solutions in waste disposal logistics.

Continuity and adaptability, high diversification in terms of customers, regions, markets, and products, as well as a stable organization and economic independence are what set us apart. We are building on this to continue growing worldwide with investments in modern technologies and sustainable products.

You can find more on this and the following exciting topics in this issue of K>MOBIL:

- Editorial: “Change and consistency” – a look back at 2025

- Compliance challenges in the automotive supply chain

- Generational change in the management of KIRCHHOFF Automotive and ZOELLER

- Successful trade fair appearances

- Awards for innovation, sustainability, and operational excellence

The publisher of K>MOBIL, Arndt G. Kirchhoff, and the entire editorial team wish you enjoyable reading, relaxing holidays, and a good start to a successful new year.

Here, you can download K>MOBIL.

04-11-25

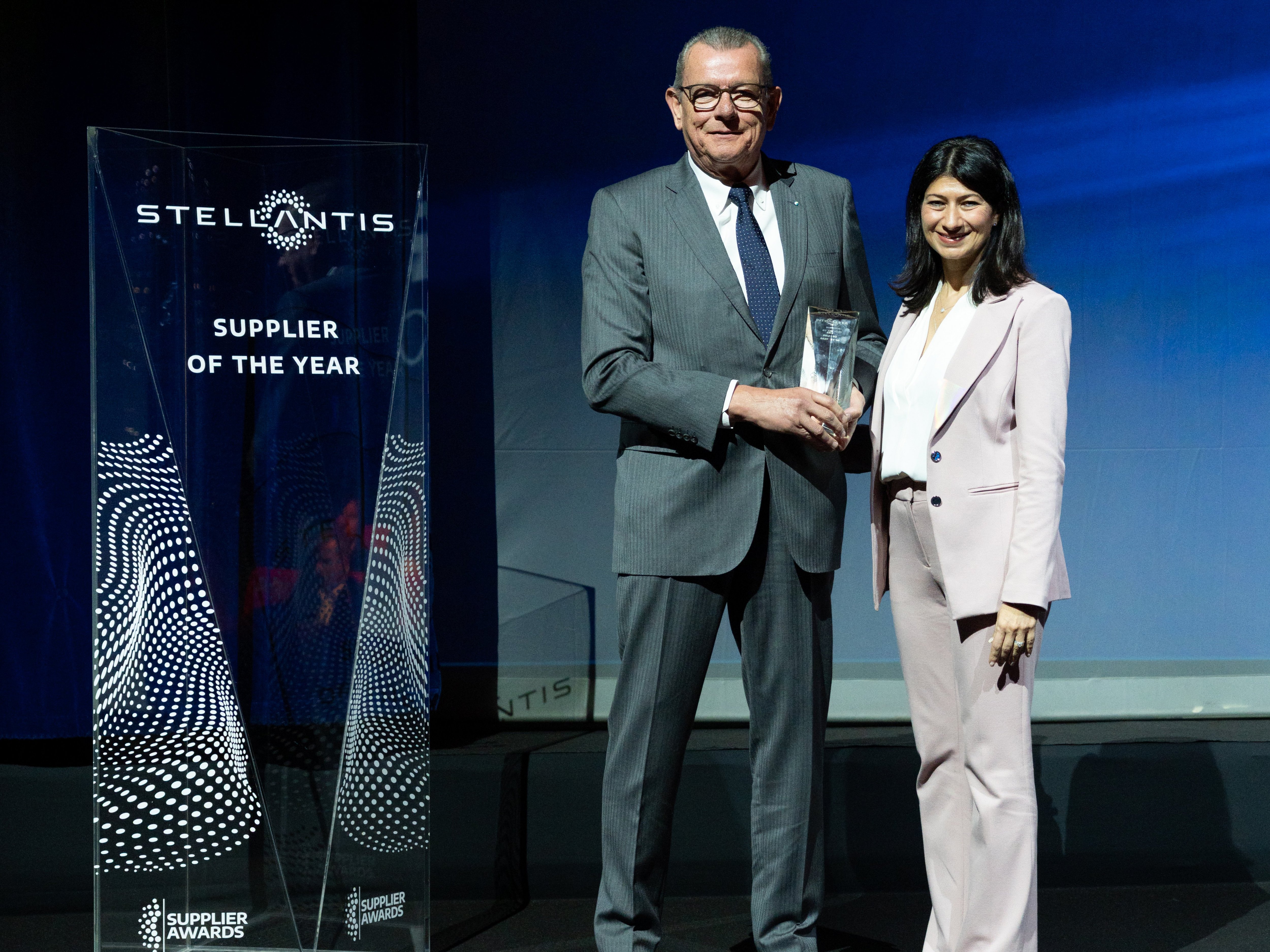

STELLANTIS Honors KIRCHHOFF Automotive as “Supplier of the Year”!

We are delighted and proud to announce that on October 28 in Paris, KIRCHHOFF Automotive was recognized by STELLANTIS as one of only 20 outstanding suppliers worldwide with the title “Supplier of the Year” – out of several thousand suppliers globally!

The automotive manufacturer STELLANTIS, whose brands include Peugeot, Citroën, Fiat, Chrysler, Dodge Ram, and Jeep, honored our exceptional performance, reliability, and continuous commitment to operational excellence with this award.

The prestigious ceremony took place during the fifth annual STELLANTIS Supplier Awards. The event was hosted by Chief Purchasing Officer Monica Genovese, accompanied by the STELLANTIS Executive Leadership Team. Over 200 partner companies attended, and inspiring keynotes covered topics such as product strategy, brand development, customer experience, and quality.

We were particularly recognized in the category “Program Management.” In 2024, we successfully launched several global programs for STELLANTIS – including the establishment of our new plant in Puebla, Mexico, to support Jeep’s KM program.

Additionally, we stepped in on short notice for another supplier and delivered technical solutions and prototypes in record time. This rapid and flexible response was crucial to keeping the program on track.

Our CEO and Chairman, Wolfgang Kirchhoff, emphasized: “At KIRCHHOFF Automotive, product development and industrialization run in parallel – the connecting element is project management. For over 25 years, we have demonstrated our expertise in this discipline, particularly when building new plants for STELLANTIS.”

This award is a tremendous achievement for our entire company – it belongs to all of us! We are thrilled about this recognition and thank all KIRCHHOFF Automotive employees for their tireless dedication, innovative spirit, and passion.

The nominees and winners were selected by a global, cross-functional STELLANTIS team. Evaluation criteria included performance, innovation capability, alignment with STELLANTIS values, and shared objectives.

Let’s celebrate this success together – it’s proof of our strength and commitment!

09-09-25

“An important company in South Westphalia”

German Chancellor Friedrich Merz visited the KIRCHHOFF Automotive stand at the IAA Mobility in Munich. J. Wolfgang Kirchhoff (Chairman of the Board and CEO of KIRCHHOFF Automotive) presented him with a B-pillar made from the innovative SIBORA steel grade, which the company developed in collaboration with Volkswagen and other development partners.

Focus on innovative steel technology

The hot-formed B-pillar made of silicon-boron steel was recently awarded the Swedish Steel Prize. Particularly noteworthy is the variable hardness adjustment achieved through different temperature control in the production process. “We develop for our customers according to their priorities,” said J. Wolfgang Kirchhoff, explaining this year's trade fair motto, “Engineered for your Needs.” “The priorities may lie in costs, lightweight automotive construction, or, in particular, sustainability. We achieve these goals through a wide variety of materials and manufacturing processes.”

Personal tribute by the Federal Chancellor

Federal Chancellor Friedrich Merz, who visited the stand together with Minister President Markus Söder (Bavaria), Minister President Winfried Kretschmann (Baden-Württemberg), Federal Minister of Transport Patrick Schnieder, Federal Minister of Economics Katherina Reiche, and VDA President Hildegard Müller, praised the company's innovative strength. “This is an example of how we also have high-performance supplier companies in North Rhine-Westphalia that produce worldwide and are recognized globally,” said Friedrich Merz. The Federal Chancellor, who knows the Kirchhoff family from their shared neighborhood in the Sauerland region, warmly thanked the three brothers J. Wolfgang Kirchhoff, Arndt G. Kirchhoff (Chairman of the Supervisory Board of the KIRCHHOFF Group), and Dr. Johannes F. Kirchhoff (Chairman of the Management Board of KIRCHHOFF Ecotec) and emphasized: “The KIRCHHOFF Group is an important company and an important employer, especially in South Westphalia.” In closing, he wished them “every success in the further development of the company in the coming years and decades.”

KIRCHHOFF Automotive will be exhibiting at IAA MOBILITY until September 12 at booth C30 in Hall B1.

18-08-25

Our customized innovations at IAA Mobility 2025

Following our great success at Auto Shanghai in April, we are now looking forward to IAA Mobility in Munich, where we will once again be presenting our innovations and demonstrating how we are making mobility safe, lightweight, cost-efficient, and sustainable. Under the motto “ENGINEERED FOR YOUR NEEDS,” we will present customized solutions that are precisely tailored to the specific requirements of our customers.

Cross Car Beams: Diversity in Safety

We will showcase the entire range of our cross-car beam technologies. From proven steel sheet construction to innovative aluminum designs and pioneering hybrid constructions (tube-in-tube), every solution is precisely tailored to the vehicle architecture and safety requirements of the respective customer. We are particularly proud of our series parts for Lixiang and Volvo XC40, which demonstrate how different material approaches deliver optimal results.

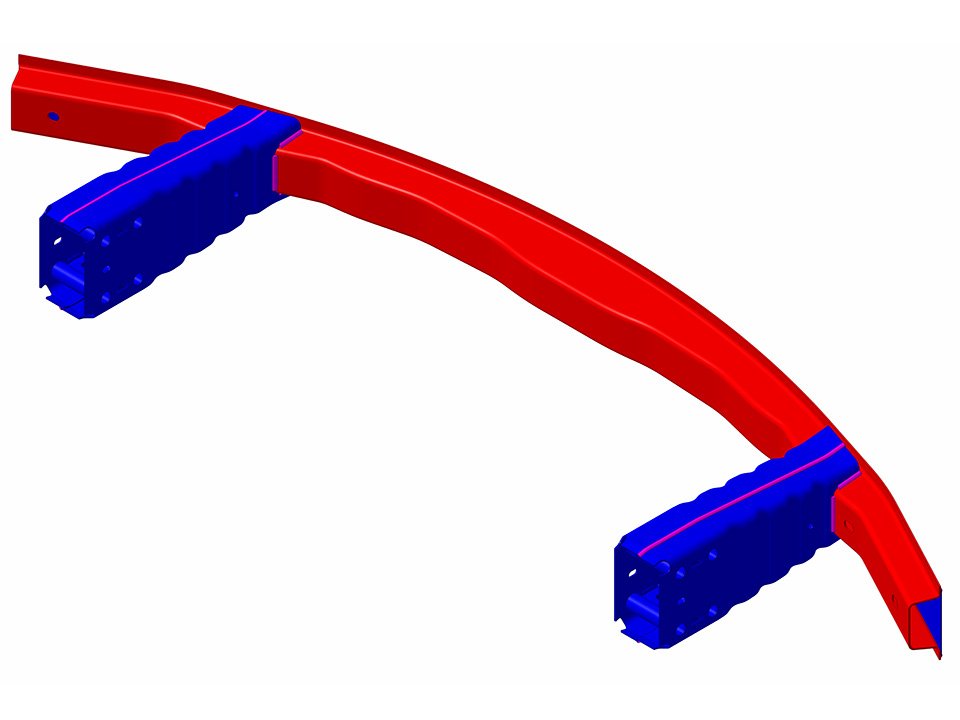

Crash management systems: Customized safety solutions

Our crash management systems illustrate how we develop the right solution for every type of vehicle. Whether cold-formed steel, partially hot formed components or aluminum designs, each system is individually tailored to the crash requirements and design specifications. Series parts from Stellantis Smart Car to Jaguar E-Pace demonstrate our international expertise and manufacturing competence.

Body-in-white structural parts: Precision for every vehicle concept

Our body-in-white components are perfectly tailored to the respective vehicle architecture. Each part is developed and manufactured according to our customers' exact specifications and requirements, e.g., the A-pillar made of Sibora for the Porsche Panamera, B-pillars with innovative 2D patch technologies, or specialized underride protection systems.

The four pillars of our engineering expertise are

- Innovation: Continuous development of our technologies for the mobility of tomorrow

- Lightweight construction: Weight-optimized solutions for better efficiency and range

- Cost savings: Cost-efficient manufacturing without compromising on quality and safety

- Sustainability: Sustainable materials and production processes for a green future

Visit us at IAA Mobility from September 9-12, 2025, in Hall B1, Booth C30! We will be posting regular updates on our social media channels during IAA MOBILITY. Follow us on LinkedIn and Instagram to stay up to date with the latest news!

06-08-25

Federal Minister for Economic Affairs Katherina Reiche visits KIRCHHOFF Automotive plant in Iserlohn

As part of her summer visits, Federal Minister for Economic Affairs and Energy Katherina Reiche was a guest at KIRCHHOFF Automotive in Iserlohn, where she expressed her appreciation for the long-established family-owned company. “I am always impressed by the group's innovation and adaptability, its international positioning, its technological expertise, and also its high level of social responsibility in the Sauerland region and beyond,” said the minister during her visit.

Discussion about the future of Germany as an industrial location

Together with Arndt G. Kirchhoff, Chairman of the Supervisory Board of the KIRCHHOFF Group and President of the North Rhine-Westphalia Employers' Association, Minister Reiche discussed the current challenges facing German SMEs and the strategies needed for sustainable growth. “Today we talked about how Germany can grow again, how we can stimulate growth, and how the Sauerland region can remain one of the strongest industrial regions in Germany,” explained the minister. She emphasized that the Kirchhoff family are “great champions of the social market economy, of competition, and of growth.”

Investment in future technologies as the key to success

Reiche cited openness to change and continuous investment in new technologies as decisive factors for Germany's future viability. During a tour of the production facilities with production manager Thomas Lozinski, the minister was able to see for herself how the KIRCHHOFF Group is focusing on automation and artificial intelligence.

Sauerland as a prime example of German industrial SMEs

“The Sauerland region is a fine example of Germany's strength – namely, its industrial SMEs,” emphasized the minister. “We want them to remain global market leaders. That is why Germany must grow again, why we must become competitive again, so that investments can be made here and industrial jobs can be retained here.”

Arndt G. Kirchhoff expressly supported the minister's statements: “On behalf of the entire German industry, the skilled trades, and the construction industry, I would like to support the Federal Minister for Economic Affairs in her view that we will only achieve our goals by changing, which means working longer or harder overall.”

At the end of her visit, Minister Reiche wished “the family and the workforce all the best.”

Images: Pia Mertens

22-07-25

Engineered for your Needs

That's what KIRCHHOFF Automotive delivers with our customized product solutions. In line with our motto MAKING.MOBILITY.SAFE., we will present body components at this year's IAA Mobility designed to make the mobility of tomorrow safe. Our focus is on cost-effective, holistic and systemic lightweight construction with optimally used materials.

We support our customers with the right technology for every technical and economic challenge. Crash-resistant, material-optimized and CO2-reduced – we offer the solution.

The IAA Mobility is one of the most important international platforms for forward-looking mobility solutions. The experts of KIRCHHOFF Automotive will be happy to show visitors the full range of our manufacturing expertise.

What you can expect from us:

- Advanced, validated body-in-white and chassis solutions with CO₂-reduced steels, developed in collaboration with leading steel manufacturers

- Innovative manufacturing process with new steel grades – for improved crash performance with lower material usage

- The optimal solution for every requirement: individually tailored manufacturing technologies and material applications

Experience our latest innovations live at the trade fair. Visit us from September 9-12, 2025 in Hall B1, Booth C30 and be inspired.

18-06-25

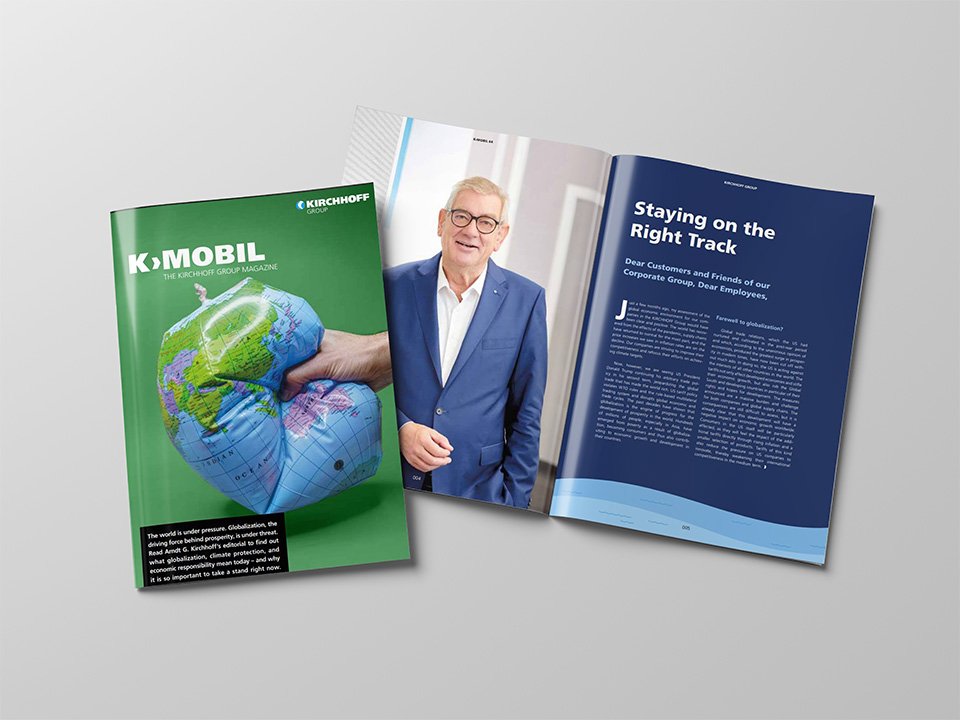

Read now: The new summer edition of K>MOBIL is here!

Globalization, partnerships, and technological innovation – these are the topics that drive us and ensure our long-term success as a company.

In the latest edition of K>MOBIL, we show how we, as the KIRCHHOFF Group, are responding to global challenges with a clear strategy, strong cooperation, and innovative solutions.

One highlight: our SIBORA steel technology, developed jointly with customers and partners and winner of the Swedish Steel Prize, enables lighter and safer vehicle structures.

Here is a brief preview of selected topics from the current issue:

- Editorial: “Staying on the right track”

- Sustainable production through innovative technologies

- SIBORA and the BQP process – award-winning!

- Trade fair reviews: Auto Shanghai & BAUMA

- Data analysis at WITTE Tools

- Special vehicles for waste collection

- Growth and new products at the ZOELLER Group

It's worth taking a look – find out more about the people, ideas, and technologies that drive our company forward.

The publisher of K>MOBIL, Arndt G. Kirchhoff, and the entire editorial team hope you enjoy reading this issue and wish you a relaxing and enjoyable summertime.

In addition to the digital version for download, printed copies will be available from mid-December in the entrance areas and canteens, or at other central locations in our plants.

13-05-25

Awarded the Swedish Steel Prize

Together with Volkswagen AG, KIRCHHOFF Automotive as SIBORA development partner has won the prestigious Swedish Steel Award 2025 for the modified BQP hot forming process and the steel grade “SIBORA”! The award was presented on May 8 in Stockholm by the Swedish steel company SSAB.

Award-winning innovation: BQP process and SIBORA

They prevailed against three strong international competitors who were also among the finalists. The jury recognized our modified hot forming process (BQP process) and the revolutionary silicon-boron steel grade “SIBORA”, which we developed in close cooperation with Volkswagen.

The innovation impressed with its outstanding properties:

- Increased safety: SIBORA material shows improved crash safety due to higher energy absorption

- Sustainability: simultaneous reduction of the body mass

- Unique material properties: High strength in the hot formed state with improved residual formability due to bainite and metastable retained austenite components

- Production-ready technology: Tests on prototypes under real production conditions have already been successful

For years, the Swedish Steel Prize has recognized outstanding engineering achievements, collaborations and steel innovations that contribute to a better and more sustainable world.

“This award impressively confirms our innovative strength and our ability to develop pioneering solutions for the automotive industry. The successful collaboration with Volkswagen and other development partners shows what is possible when leading companies pool their expertise,” commented Technology Development Senior Specialist Markus Löcker, who accepted the award on behalf of KIRCHHOFF Automotive.

Outlook

The award-winning technology opens up new possibilities for the design of lighter and at the same time safer vehicle structures. The first prototypes have already been successfully tested and we are working intensively on further optimization for series production.

The Swedish Steel Prize 2025 is a confirmation of our corporate strategy of actively shaping the mobility of the future through innovation and sustainability.

07-05-25

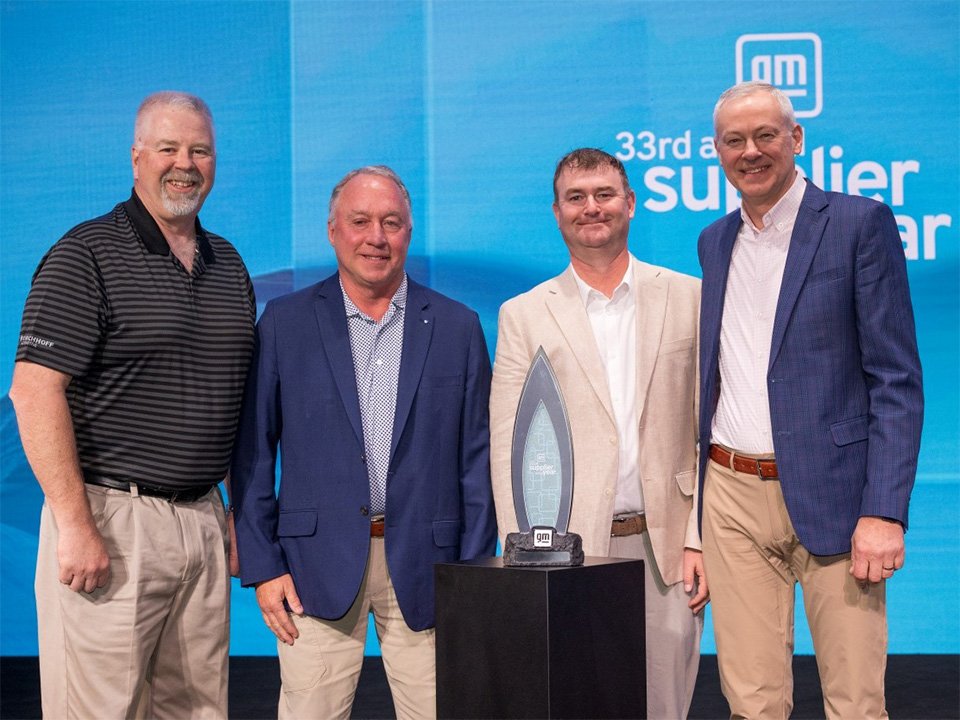

“Supplier of the Year 2024” by GM

Each year, General Motors (GM) acknowledges its most exceptional suppliers during the prestigious “Supplier of the Year” event. This year there were 92 suppliers across 12 countries recognized, including KIRCHHOFF Automotive which was proudly presented with the “Supplier of the Year 2024 in the Creativity Team of Structures” award.

Larry Hagood, President & CEO of KIRCHHOFF Automotive North America, Ken Hagle, Director of Sales, and Josh Forquer, Executive Vice President of Sales and Technical Development, accepted the award in Phoenix, Arizona, in early April. “Receiving this award in consecutive years is a great achievement for us, as it reflects our long-term commitment to meeting GM’s quality, delivery, and cost targets,” said Larry Hagood. “Since only a small fraction of GM’s global supply base receives this award, we are very proud to be among this very exclusive group and look forward to working with GM to achieve these targets in the future.”

In the selection process, GM evaluates suppliers based on their comprehensive performance throughout 2024, with a particular emphasis on alignment with GM's core values and strategic objectives. This recognition underscores our continued commitment to excellence and partnership with one of the world's prominent automotive manufacturers.

“For more than 30 years, General Motors has recognized the company’s top global suppliers at our annual event, spotlighting their innovation and resiliency through even the most challenging circumstances,” said Jeff Morrison, global chief procurement officer at GM. “Together, we’re helping bring advanced technology and the industry’s broadest portfolio of vehicles to market for GM customers.”

06-05-25

That was Auto Shanghai 2025!

Ten days full of highlights, innovations and surprises are over. “Stylish”, “innovative”, ‘influential’, “massive” - that's how our colleagues who were there describe the exhibition. Safety, artificial intelligence and connectivity are major topics for many new models.

Take a look back at the world's largest motor show in our video.