08-11-24

“A sensational trade fair”...

is our conclusion of the IZB 2024. At the start of the International Suppliers Fair (IZB) in Wolfsburg, Germany, which took place from October 22-24, the Group and Brand Board of Management of Volkswagen visited us – as one of only six of the 843 exhibitors at this trade fair!

Around 50 members of the VW Board of Management, including Oliver Blume (Chairman of the Board of Management of Volkswagen AG and Dr. Ing. h. c. F. Porsche AG) and Dirk Große-Loheide, Board Member for Purchasing at the Volkswagen Passenger Cars brand and member of the extended Group Management Board, learned about our innovations during this VIP Tech Walk. The theme of the tour was “Accelerating marketable products.” The focus: a joint research project with VW Group Innovation on the use of a new steel grade made of silicon-boron steel “SIBORA”. This has high strength in the hot formed state and, thanks to its bainite and metastable retained austenite content, also has a higher residual formability. Successful tests of a hot-formed B-pillar made of “SIBORA” material under series production conditions show that an improvement in crash safety can be achieved as a result of higher energy absorption with a simultaneous reduction in body mass.

In addition to the product innovations made of “SIBORA” material, KIRCHHOFF Automotive also presented a steel module cross member in open shell design at the IZB, which is not only lightweight but also allows the integration of cable harnesses, for example.

One of our main goals is to develop and produce products that make car bodies more environmentally friendly. That is why we have validated the use of new CO2-reduced steels in cooperation with leading steel producers. At the IZB, for example, we presented an Audi sill on which we successfully tested the use of ArcelorMittal Usibor®1500 XCarb® recycled and renewably produced substrate as a starting material. This material consists of at least 75% recycled steel and 100% renewable electricity in the steelmaking process. This enables us to significantly improve the carbon footprint of our products.

This also made us a valued discussion partner at the IZB “Green Steel” workshop. The topics discussed included challenges for calculating the carbon footprint of products, challenges in the transformation to green steel and climate neutrality targets.

Dr. Thorsten Gaitzsch summarizes: “The discussions with the representatives of the Board of Management and the dialogue with VW experts in a small group were a special highlight, as they gave us important insights and at the same time further strengthened our partnership.”

For lightweight construction and safety - these were our highlights at the IZB

1 .The first use of the revolutionary ‘SIBORA’ silicon-boron steel grade, developed in cooperation with Volkswagen AG and successfully tested on various prototypes

Hot forming is a forward-looking, effective technology that can significantly reduce the CO2 footprint of a component. The use of materials plays a crucial role here. Together with VW, KIRCHHOFF Automotive has therefore worked on the material and process development of a silicon-boron steel grade called ‘SIBORA’ for a modified hot forming process, the so-called BQP process. SIBORA is a new steel grade that exhibits high strength in the press-hardened state and, due to the content of bainite and metastable residual austenite, also higher residual formability. By using the steel grade “SIBORA”, an improvement in crash safety can be achieved as a result of higher energy absorption with a simultaneous reduction in body mass.

2. Safety-relevant products made of new CO2-reduced steels for an improved ecological balance and more environmentally friendly car bodies

With special body-in-white solutions, KIRCHHOFF Automotive ensures safe mobility, primarily through the high strength of special steels. An additional advantage: less material is needed for products made of such steels. This saves weight and effectively contributes to the reduction of the CO2 footprint. In cooperation with leading steel producers, we have validated the use of new CO2-reduced steels. This enables us to significantly improve the CO2 balance of our products. At the IZB, KIRCHHOFF Automotive exhibited an Audi sill, for example, on which the use of ArcelorMittal Usibor®1500 XCarb® recycled and renewably produced substrate was successfully tested as a primary material. This material consists of at least 75% recycled steel and 100% renewable electricity in the steel production process.

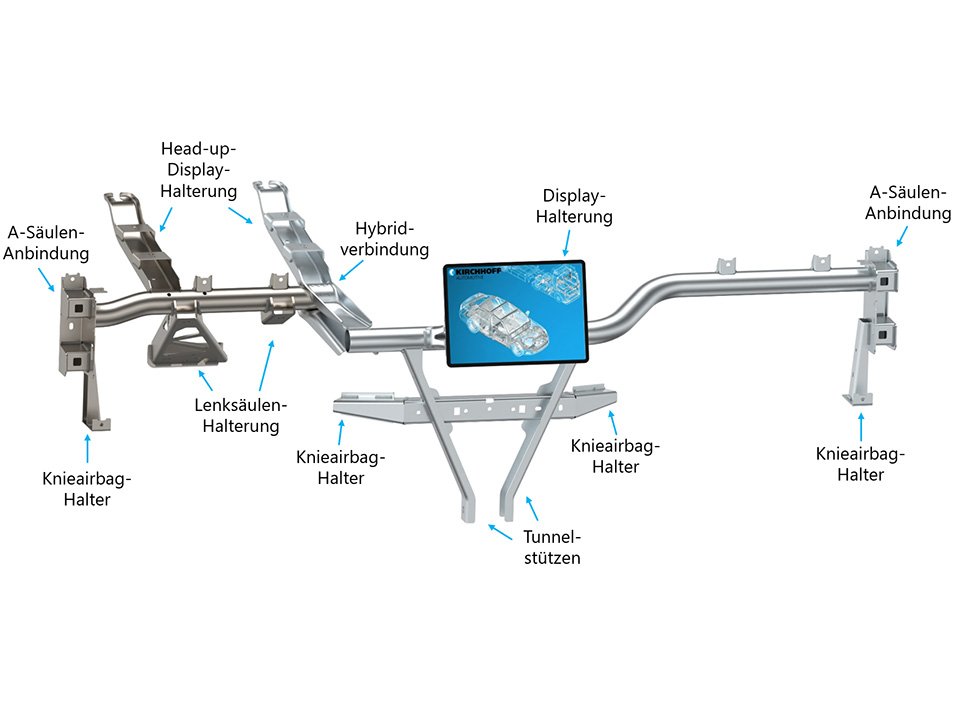

3. Function integration in the cockpit: Innovative steel module cross-car beam in open shell design

KIRCHHOFF Automotive complements its extensive manufacturing portfolio for this product group with the instrument panel carrier in open shell design. The steel modular cross member is not only lightweight, but also enables the integration of cable harnesses, for example. A major advantage of this design is the high level of functional integration, which helps to reduce costs.