09-02-22

Workforce Development and Investing in the Latest Technology

A detailed article describing the situation (or measures) in our North American plants has been published in the current February issue of American magazine, MetalForming.

Recognized worldwide as a leader in providing stamped parts such as welded assemblies, cross car beams, bumper systems, and further metal and hybrid structures, our company is at the center of the evolutionary swirl encapsulating this rapidly evolving market. In doing so, we have tuned our senses to react to new challenges every day, such as electrification, light weighting, new steel and aluminum grades, reduced lot sizes, shortened lead times and, of course, workforce and supply-chain hiccups.

"We’re heavily invested in training our workforce and providing them with state-of-the-art stamping and welding technology," says Joshua Forquer, Executive Vice President of Sales and Technical Development at KIRCHHOFF Automotive in Troy, USA. He adds that this clears the path to continued success.

Joshua Forquer eyes servo-press technology as providing a sizable competitive advantage for the North American plants, particularly for forming advanced high-strength steels. The plant in Tecumseh, USA alone has 14 presses with press forces of 250 to 1,650 metric tons. Six of these have been newly commissioned since 2017. But it is not only technology that is important, but also employee job satisfaction. "We're committed to building trust and stronger relationships between management and the workers on the floor," adds Forquer, "which we believe will come with our growing commitment to training and investing in our employees." One key to this is the recent investment in a series of online training modules.

Employee development is also of central importance in the welding sector. Missy Smith, Plant Manager in Lansing, USA, works closely with union leadership on workforce development initiatives. For example, as a member of a committee, she has developed a training program together with the Michigan Department of Labor and Lansing Community College.

In order to exchange best practices worldwide, there is the global KIRCHHOFF Automotive best-practices database called GoBench. "We use this for cross-facility benchmarking – any competitive advantage or process development reside in this global database. These process enhancements then become available to anyone on our engineering team anywhere in the world. And, if our management team labels a process enhancement as a global standard, every facility must budget to implement that process to improve their performance," explains Joshua Forquer.

Read the full article in MetalForming magazine here.

Info: MetalForming Magazine

MetalForming is a monthly magazine with a circulation of over 53,000 copies, aimed at engineers, technicians, managers, designers and others working in facilities that add value to sheet metal. Readers are involved, for example, in the manufacture of fabricated metal products, automotive stampings, electric and electronic equipment, appliances and other similar products. MetalForming aims to provide them with tools they need to do their job better.

27-01-22

Successful Support Program: From Homeless to Team Leader

Helping people overcome drug addiction and find a new start: our plant in Waverly, USA supports former drug addicts with special programs that help support them in making a new start in their careers.

Our colleague Ben Buck participated very successfully in such a program – today he leads the Honda Accord team in the plant and has been clean for almost seven years.

The story of Ben Buck sounds like a Hollywood drama with a happy ending. But, it really happened. It encourages others to make a fresh start. Ben participated in the Transitions Work Experience Program in Scioto County, Ohio. There is a similar program in Pike County, where our Waverly facility is also involved.

Poor decisions early in life sent Ben to prison for seven years, followed by homelessness and turning back to drug addiction. After a near fatal overdose, his kids became the reason Ben sought treatment and a fresh start. "I was living in the back of a Jeep Cherokee, filling out thousands of employment applications. I always answered truthfully when asked if I had ever been convicted of a felony," Ben said, even though he knew that it was likely the reason he would not be hired. He had quickly lost faith in the community, industry, and apparent programs that seem to offer support.

But Ben didn't give up. "In 2017, I came to KIRCHHOFF Automotive in Waverly as a temp. I was excited to be working a really decent job. I worked harder than anyone else. I was always honest with my supervisor and team lead. He was understanding and did not hold my past against me." Ben was then able to participate in the Transitions Work Experience Program, which is designed to help people transition out of drug addiction. "I was quickly offered a full-time position, and several years ago I was given the opportunity to step up and begin leading others." Today, Ben Buck leads the Honda Accord team in Waverly; they produce the cross car beam for this vehicle on a complex assembly cell.

In the past five years, Ben has lost over ten friends and relatives to drug addiction. "It tears your life apart. I feel very fortunate to have overcome this, and it has left me with a very strong belief that recovery and employment go hand-in-hand." He celebrated his birthday on January 13, which marks 82 months of being clean.

"We are so thankful for Ben and his passion and commitment, not only to the Waverly plant, but also to those coming from similar backgrounds," said Plant Manager Mel Fultz. "We remain committed and engaged to do as much as we can to help our community combat this plague."

Ben Buck is also grateful to our company and for participating in the Transitions Work Experience Program. "Tomorrow I could start working at another company in Waverly. But that company didn't save my life."

Further Information: Transitions Work Experience Program

The program in the Pike County region of Ohio, USA has been in place since 2019. It is designed to help those affected by substance abuse transition out of addiction and reorganize their work lives. Adult employees with technical work experience can acquire basic skills and learn professional etiquette in the form of internships. In May 2020, we established an internship site in Waverly for the program. A total of eleven interns participated last year. More than half of them were offered full-time employment and more than a third will continue to work full-time at our plant.

24-01-22

No One Will Be Lost

The President of the VDA (German Association of the Automotive Industry), Hildegard Müller, visited the Attendorn-based automotive supplier companies KIRCHHOFF Automotive, Mubea and the Automotice Center Südwestalen (acs) on January 18. The main topics of the talks were demography and shortage of skilled workers as well as current issues around material supply and raw material prices.

All those involved in the talks - including our shareholders Arndt G. Kirchhoff and J. Wolfgang Kirchhoff - agreed that domestic companies must make their employees fit for the transformation - no one will be lost. Another important topic of the talks was energy costs and, above all, energy volumes: Where is all the electricity supposed to come from, according to the political directive? Apart from the fact that we lack thousands of charging points for e-vehicles, where does the electricity from the gas pump come from?

In addition to KIRCHHOFF Automotive, Hildegard Müller visited the companies Mubea and acs. The acs is our partner in the research and development of innovative body structure parts. This collaboration has resulted, for example, in a hybrid instrument panel beam and a pre-galvanized crash management system with high deformation capacity, which we presented at the IAA Mobility in Munich.

Hildegard Müller succeeded Bernhard Mattes as VDA President on February 1, 2020.

07-01-22

Developed in Collaboration: Luxury E-Car for the Chinese Market

In recognition of our outstanding performance in developing a luxury electric car last year, our Chinese plants received a letter of thanks from Liao Zehua, Head of Supply Chain at Lixiang Auto.

Last year, KIRCHHOFF Automotive (KA) in China and vehicle manufacturer Lixiang Auto worked together to develop a luxury brand electric car. Together, the two companies were able to overcome all the challenges involved, successfully improving sales from 5,379 in January to 14,087 in December – nearly triple the increase! A single model of the EV brand was able to sell over 10,000 vehicles in November and December respectively. Our teams from Sales, Research & Development, Production, and Logistics have thus demonstrated that they deliver outstanding performance in the automotive industry.

Liao Zehua, Head of Supply Chain at Lixiang Auto, sent a thank you letter to Wen Leyendecker, Managing Director of KA China. In doing so, he showed his appreciation for our hard work and commitment. In the letter, he expresses his trust in and praise for KA China, and expresses his hopes for future development and cooperation.

"2022 will be a crucial year for Lixiang Auto and KIRCHHOFF Automotive in China to capture the huge electric car market. We will continue to work together to master a future full of challenges and opportunities!" said Liao Zehua.

Wen Leyendecker replied: "It is also a great honor for us to cooperate with such a fast-growing luxury electric vehicle brand like Lixiang Auto, and it will be our constant mission and responsibility to ensure product quality and continuous supply. In the new year, we will continue to leverage our strengths as an expert supplier of aluminum products to deliver innovative, safe, and lightweight products. We look forward to further success in our cooperation on new models!"

17-11-21

Setting a Sign for the Environment

In 2020, KIRCHHOFF Culture Life launched its tree planting campaign: 1,785 trees were to be planted at all KIRCHHOFF Group sites. Now, additional employees in Germany, Poland, Portugal, Hungary, and Italy have joined the initiative.

"It was a great campaign - sustainability for the whole family. We helped to give the barren landscape a new face again," says Peter Kampschulte, Plant Manager Forming in Attendorn, Germany. Around 30 employees planted 60 winter lime trees at the German sites on the first weekend in November.

“An amazing project! It’s great to see how many children are involved. Trees for the future, where children are our future. Projects like this can change the mindset of many people. I am proud to part of this KIRCHHOFF Culture Life project,“ says Giorgio Aschieri, Farid Ind./KIRCHHOFF Group, Vinovo, Italy.

“We love this idea to get employees and their families on board for an important project for our environment. It’s a great initiative and fun to be part of!“ say Géza Körtvélyessy and Szilárd Méri, Managing Directors at KIRCHHOFF Automotive in Esztergom, Hungary.

The activities were organized by our cultural representative, Thomas Kirchhoff: "It is a pleasure to see how many employees and their children support our initiative in such a great and enthusiastic way. In the end, we will have planted almost 100,000 trees for the future - a drop in the bucket, but a steady drop wears away the stone."

The number 1,785 stands for the founding year of the KIRCHHOFF Group. Together with local tree nurseries and forestry offices, employees and their family members can participate in the campaign. This way, we can set a global example on how to cherish our environment and the future of our children.

15-11-21

For More Responsible Supply Chains

KIRCHHOFF Automotive is one of the 15 founding members of the association Responsible Supply Chain Initiative RSCI e.V. The aim of the association is to support all stakeholders in the automotive sector by establishing a high level of sustainability in supply chains.

The German Association of the Automotive Industry (VDA) is working with manufacturers, suppliers, and other associations to develop a standardized test procedure for evaluating the sustainability performance of companies in automotive supply chains. Christian Arens, Key Account Manager in our Daimler team, was present at the founding meeting on October 28, 2021.

"Companies’ careful duty towards the environment and people has become a central issue in our industry in recent years. For some time already, we at KIRCHHOFF Automotive have been committed to the joint development of suitable instruments to promote sustainable corporate policy. By founding the association, we are underlining the relevance of the topic and have the opportunity to consolidate our activities in dialog with vehicle manufacturers, suppliers, and associations," says Christian Arens.

The association aims to review and further develop the sustainability of companies in their supply chains. It has developed a special program for on-site investigations and follow-up. With this program, the effort, costs, and eventually the results, can be shared. In order to create transparency about working conditions, tests are carried out directly at the production site. The program promotes supplier development and contributes to the further development and continuous improvement of sustainability.

"The standardized audit mechanism was developed in close cooperation with our customers. I am convinced that the path we have taken is target-oriented and accompanies the process in a meaningful way for all involved parties. The establishment of the association gives us the opportunity to apply the standard internationally as well," Christian Arens concluded.

The operational phase will start at the beginning of 2022, in which the founding members will carry out initial risk-based pilot audits.

Founding Members of the association RSCI e.V.:

- AUDI AG

- Bayerische Motoren Werke AG (BMW Group)

- Brose Fahrzeugteile SE & Co. KG

- CLEPA AISBL

- Business Network for Corporate Responsibility AISBL

- Daimler AG

- Dr. Ing. h.c. Porsche AG

- Ford-Werke GmbH

- KIRCHHOFF Automotive GmbH

- Magna International (Germany) GmbH

- MAN Truck & Bus SE

- Robert Bosch GmbH

- Schaeffler AG

- Verband der Automobilindustrie (VDA) e.V.

- Volkswagen AG

Please find attached a press release (English) by the VDA on the foundation of the association.

28-10-21

"The switch to digital must lead to improvement"

In some areas, such as digital audits and digital shop-floor management, digitalization has already brought us further. But it is not an end in itself. In this interview, Stefan Leitzgen, Managing Director and Global COO, talks about the challenges and potential of digitization.

What are the biggest challenges in digitization?

A major challenge is the valid assessment of the cost-benefit ratio. Many things are technically possible, but often bring only minor benefits. The permanent costs for hardware and software and the additional CO2 impact reach a relevant order of magnitude for many digital solutions when looked at closely. Added to this are questions of data security and protection against hacker attacks.

At the moment, our teams around the world are being sensitized to be careful on their PCs and not to download any malware that reaches us via fake e-mails. How should we imagine the threat in production?

Digital solutions within our own corporate network are well secured by our extensive cyber security measures. But every interface to the Internet is a potential source of danger.

In which areas do we see the greatest potential for digitization?

I see great potential in the analysis of machine and process data. With the help of machine data, we can identify at an early stage what we need to do to avoid malfunctions and how energy can be saved. Through the extensive analyses of process data, we can once again significantly improve the quality of our products.

Can you give a few examples where digitization has already helped us?

Among other things, we have introduced electronic signature, digital audit and digital store floor management. This saves us tons of paper every year. And we are making great progress in building our digital manufacturing platform. This will later network all the machines, equipment and transport systems in our factories.

What are the next projects we will see in the company?

We are spending a lot of time and resources this year on building the digital manufacturing platform. In addition, we are working on the digitalization of our maintenance processes.

Thank you very much for the interview.

The interview was conducted by Andreas Heine, Global EVP Communication & Marketing.

09-09-21

Completely Rethinking the Security Architecture

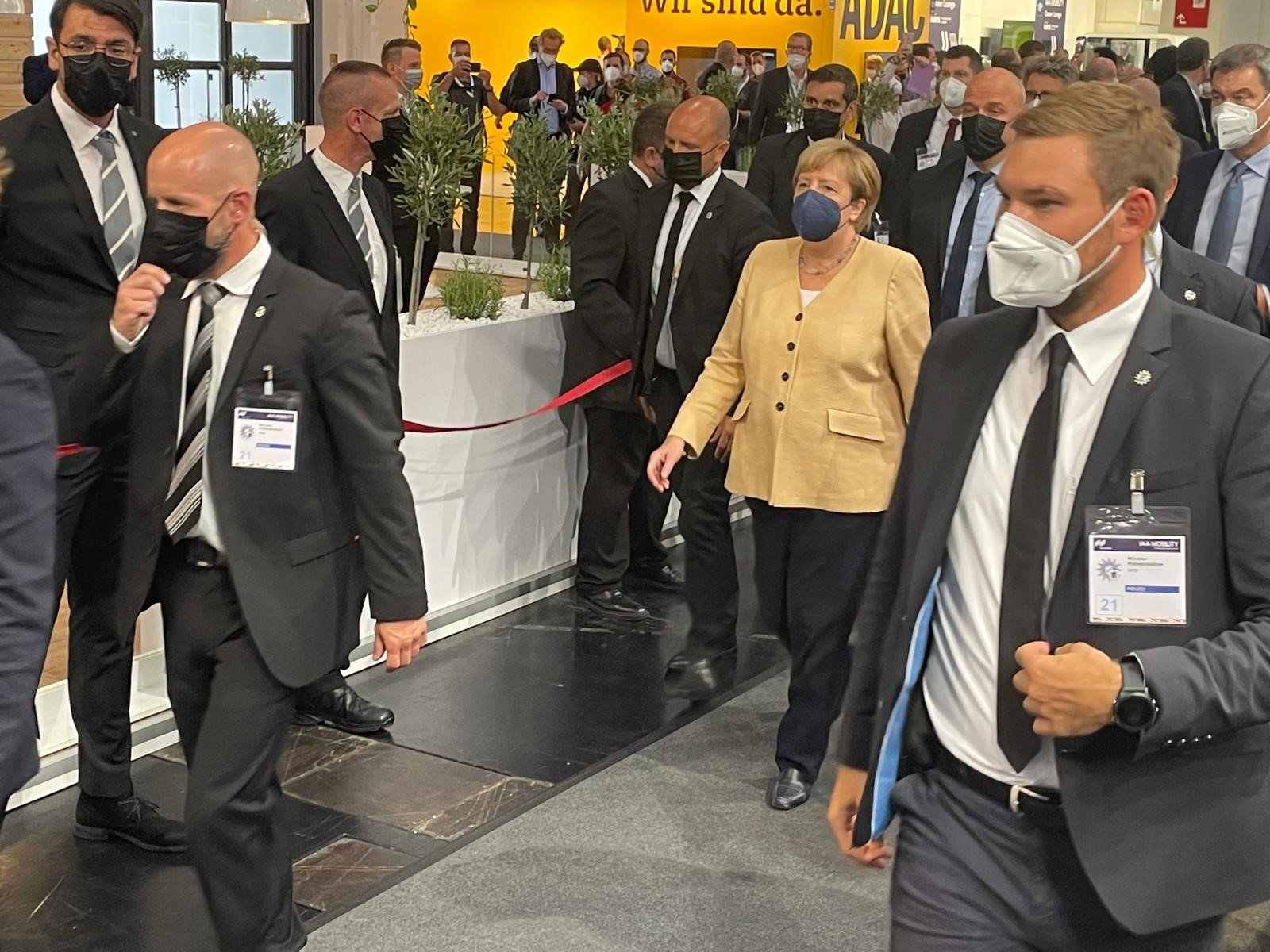

German Chancellor Angela Merkel praises the strengths of the German automotive supplier industry during her visit to the KIRCHHOFF Automotive booth at the IAA Mobility in Munich.

Arndt G. Kirchhoff and J. Wolfgang Kirchhoff welcomed the German Chancellor, who was accompanied by Markus Söder (Prime Minister of Bavaria), Winfried Kretschmann (Prime Minister of Baden-Württemberg), VDA President Hildegard Müller and Federal Minister of Transport Andreas Scheuer, to find out about KIRCHHOFF Automotive's innovations.

The focus was on a crash management system specially designed for electric vehicles and a world first instrument panel beam in hybrid design. Both whose joints are produced substance-to-substance, in a form-fit and force-fit manner and thus prevent the formation of corrosion between the two materials steel and aluminum. "These are two examples of how we are combining vehicle safety and lightweight automotive construction," explained J. Wolfgang Kirchhoff.

The Chancellor was impressed: "That's very interesting, I hadn't thought that through at all. The entire security architecture has to be completely rethought. And these are the strengths of the German automotive supplier industry - that you are thinking all this through," she said. Arndt G. Kirchhoff said that caring for vehicle safety is the main concern of KIRCHHOFF Automotive: "The number of accidents on the roads is decreasing every year. That is our main task: to continue to make cars safe in the future." After 2007, 2013 and 2017, this was the fourth visit of the German Chancellor to a

KIRCHHOFF Automotive booth at the IAA.

Here you can see a video of the visit of German Chancellor Angela Merkel at the KIRCHOFF Automotive booth. You can display English subtitles using the icons in the lower right area of the video.

08-09-21

One of the highlights: German Chancellor Dr Angela Merkel visits our stand

A short visit to KIRCHHOFF Automotive before her visit to the VW: Federal Chancellor Angela Merkel visits our stand one last time at the end of her term in office. After 2007, 2013 and 2017, this is now the fourth time that we have had the opportunity to personally present our innovations to the Chancellor.

A short visit to KIRCHHOFF Automotive before her visit to the VW: Federal Chancellor Angela Merkel visits our stand one last time at the end of her term in office. After 2007, 2013 and 2017, this is now the fourth time that we have had the opportunity to personally present our innovations to the Chancellor.

The focus of Merkel’s visit this time was on two innovations, including a world first. Angela Merkel was impressed by our developments, which are light, economical and crash-proof.

Arndt and Wolfgang Kirchhoff welcomed the Chancellor, who visited the KIRCHHOFF Automotive stand accompanied by Markus Söder (Bavarian Minister President), Hildegard Müller (VDA President), Andreas Scheuer (Federal Minister of Transport) and Winfried Kretschmann (Minister President of Baden Württemberg).

24-08-21

IAA here we come

Wondering why our global CTO Dr. Thorsten Gaitzsch is particularly looking forward to the IAA this year and why he believes trade shows are important for us even in times of digitalization? An interview with his perspective, conducted by Global EVP Communication & Marketing Andreas Heine, can be found below.

Andreas Heine: There are only a few days left until the world's leading automotive trade show, the IAA, opens its doors again. But this year, a lot is different. Thorsten, we will no longer be exhibiting in Frankfurt, but in Munich, and the event’s name is also new, IAA Mobility. Does the new name bring anything new?

Dr. Thorsten Gaitzsch: Absolutely, Mobility stands for new mobility, and by that we mean everything that people use to move around and that moves people. At the trade show, this also means bicycles, for example.

Andreas Heine: Doesn't that weaken the IAA as the world's leading trade show for automobiles?

Dr. Thorsten Gaitzsch: Not at all. We want to show that we see ourselves as part of tomorrow's mobility and are not against new forms of mobility. Quite the opposite, in cities it makes sense in many situations to leave the car behind and ride a bike. But if you do need a car, it will be emissions-free in the future and contribute to cleaner air in the city. In the countryside, the car is still indispensable in most cases.

Andreas Heine: What does the new location entail?

Dr. Thorsten Gaitzsch: We will be exhibiting in really beautiful, new exhibition halls. The whole team is looking forward to it. This time there will be a colorful mix of manufacturers and suppliers who will no longer be separated. For example, VW will be exhibiting in Hall B2, as will a new Chinese car manufacturer. In addition, there are many places in the city where you can touch and test this new mobility - everything from e-vehicles to e-bikes and much more.

Andreas Heine: What will we be presenting?

Dr. Thorsten Gaitzsch: We will be showing our share of this new mobility as we are already supplying many parts in electric vehicles and more and more are coming. An example of that would be our battery housing for the large batteries in the Volkswagen Group's current e-models. We have commissioned a completely new laser welding system in Iserlohn specifically for this purpose. In addition, we will also present world’s firsts for future vehicles, including fully laser-welded bumpers made of galvanized steel.

Andreas Heine: Why is this trade show still so important for us, when today it is increasingly possible to exchange information digitally?

Dr. Thorsten Gaitzsch: That's true, but it doesn't replace personal contact. Our business is based on long-standing partnerships with manufacturers and their trust in our ability to develop the best parts for them and find the most optimal body-in-white solutions for their challenges. That is still done best by sitting down together and looking each other in the eye.

Andreas Heine: How can employees get an impression of the trade show?

Dr. Thorsten Gaitzsch: The trade show only lasts a week this year, which means that by Friday our booth will hopefully be full of customers. For the weekend, we will raffle tickets to our employees via K>NET; and for those who can’t travel all the way to Munich, we will offer a live stream through K>LIVE on Wednesday from 5 to 6 pm local time. There, you Andreas will show the booth and certainly also conduct interesting interviews around the IAA.

Andreas Heine: That's right, we will be sending out the access data to everyone. Thank you very much Thorsten for this insight into the IAA, and in one way or another we will all see each other there.