27-02-23

Welcome KATE Teams!

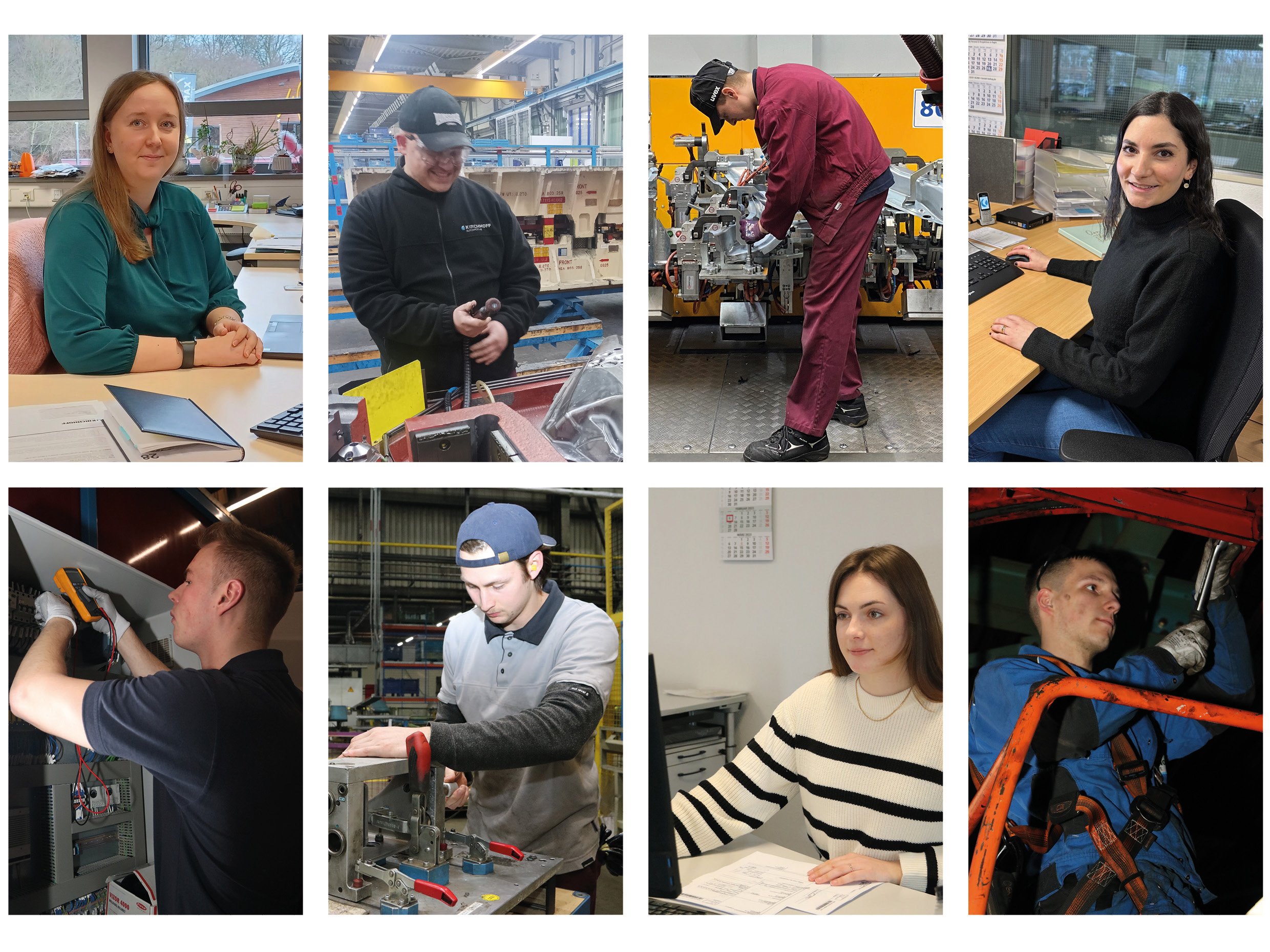

42 colleagues worldwide have enrolled in the talent management program, KATE, and are looking forward to the training and projects during the upcoming years.

KIRCHHOFF Automotive’s internal talent management program, KATE, helps develop employees who demonstrate outstanding performance and potential. Over the next years, they will participate in many training sessions and individual development projects.

“I’m very excited to have a mentor and to be a part of this program!” says Victor Tang, senior technology development specialist at Aurora corporate in Canada. He is one of the six colleagues who joined our KATE program in October 2022.

“I am very interested in expanding my leadership skills and learning more!” commented Stephen Cook, quality specialist in Lansing, USA.

Urszula Balcerek, HR country manager of Poland, thinks, "A company's opportunities for growth and success are closely linked to the development potential of its employees; an increasingly important factor in choosing an employer is the opportunity to develop and improve skills. Companies are therefore implementing development programs such as KATE at our company. The fact that the third round is now starting in Poland is not only testimony to the need for employee development, but also confirmation that talent development is a high priority in our company."

17-02-23

Reducing CO2 through induction in hot forming

Together with the German University of Paderborn and other companies, KIRCHHOFF Automotive would like to bring the inductive heating of moulded blanks for hot formed car body components to series production readiness. This could avoid a great deal of CO2 emissions. Markus Löcker, technology development specialist in Attendorn/Germany, is part of a research team working on the development of this process.

Energy by induction - this not only works at home on the stove, but can also work on a hot forming plant. "We have already been involved in initial research projects on induction heating starting in 2010. In the process, we successfully heated the head area of our B-pillar by means of induction in 2019 and then formed it in our B-pillar mold," explains Markus Löcker.

Hot forming has been an integral part of our manufacturing technologies portfolio for 15 years. This process can be used to produce high strength and very lightweight body parts. If such parts are installed in the vehicle, it has a significantly lower weight, which saves CO2.

That sounds good initially. However, the production of hot formed parts causes high emissions. "In the industrial hot forming process, sheet metal blanks are usually heated in ovens up to 40 meters long. In order to bring these ovens to a temperature of 950 degrees Celsius, fossil fuels are usually necessary," explains Prof. Dr. Thomas Tröster, holder of the Chair for Lightweight Automotive Construction (LiA) at the University of Paderborn, and board member of the "New Mobility Paderborn" (NeMo) initiative.

The project team is now researching a method of inductively heating blanks during hot forming. This works like cooking on an induction stove: electrically conductive bodies (like the cooking pot on the stove, or the blanks during hot forming) are heated with the help of an alternating magnetic field. Current flows through a coil (inductor) and generates the magnetic field. The magnetic effect induces eddy currents in the material, causing it to heat up.

"In another research project with various project partners, we are developing innovative sheet metal coatings that can be heated by induction. The AlSi (aluminum-silicon) coatings currently used do not allow complete heating by induction because they require a diffusion time at certain temperatures," Markus Löcker further explains.

If hot formed parts are heated by induction, regenerative generated electricity can be used for this purpose, thus saving emissions. Additionally, high temperatures can be reached faster and more effectively than before. At the end of the process, vehicles can be manufactured in a more environmentally friendly and efficient way. Another advantage of an induction heating system is the space requirement – compared to the roller hearth furnace, approximately 55% can be saved.

13-02-23

“Never lose your hunger for knowledge“

The fact that an apprenticeship is a good investment in the future is confirmed by the apprentices at KIRCHHOFF Automotive who have now successfully completed their training period.

"Doing an apprenticeship was a very good decision, because I learned a lot from the practical areas and can also apply that. I was able to gain an insight into the world of work and orient myself as to which direction I would like to go in after my apprenticeship," says industrial clerk Lara Schorlemmer from Iserlohn/Germany.

Till Hirschmann, industrial mechanic for operating technology in Attendorn/Germany, says: "My best experience during training was when I completed a larger project - a welding booth for rework - with an industrial mechanic from maintenance and it worked perfectly the first time I used it." He is now looking forward to learning more tricks of the trade from the journeymen and is happy to have the opportunity to complete a dual study program.

Industrial clerk Janine Bender from Attendorn recommends "deciding on an apprenticeship right after school and only studying later."

Congratulations to all on passing the exams - a great achievement! And even after training, the learning continues. "It's important to always be curious and never lose your hunger for knowledge," says Yusuf Cuhader, a tool mechanic in Attendorn/Germany.

11-01-23

The help continues

To ensure that one of the most important and largest universities in Ukraine, the National Polytechnic University of Lviv, can continue to be supplied with electricity, our colleagues from KIRCHHOFF Automotive in Poland have donated a power generator. For them it was a matter of course to help quickly and unbureaucratically.

In the presence of more than 550 employees, Janusz Soboń, Managing Director KIRCHHOFF Automotive Polska, and the CFO of KIRCHHOFF Automotive Holding, Claudius Bensberg, handed over a generator to the Head of the Ukrainian Center for Humanitarian Aid Collection, Yurii Malynovskyi. For this he expressed his sincere thanks: "Thank you very much for all you do for us and our country. Your support shows how much we stand together and in Europe one neighbor helps another. I am very pleased that our Polish partners are meanwhile even working on the delivery of consumables for the operation of the generators."

In addition, other companies and partner universities supported the Lviv University, so that a total of 19 generators could be delivered - one third of the power supply of critical infrastructure facilities is thus already secured.

Info: The National Polytechnic University of Lviv is one of the oldest and most important technical universities in Ukraine. The university consists of 18 institutes with over 30,000 students and almost 4,000 lecturers.

16-12-22

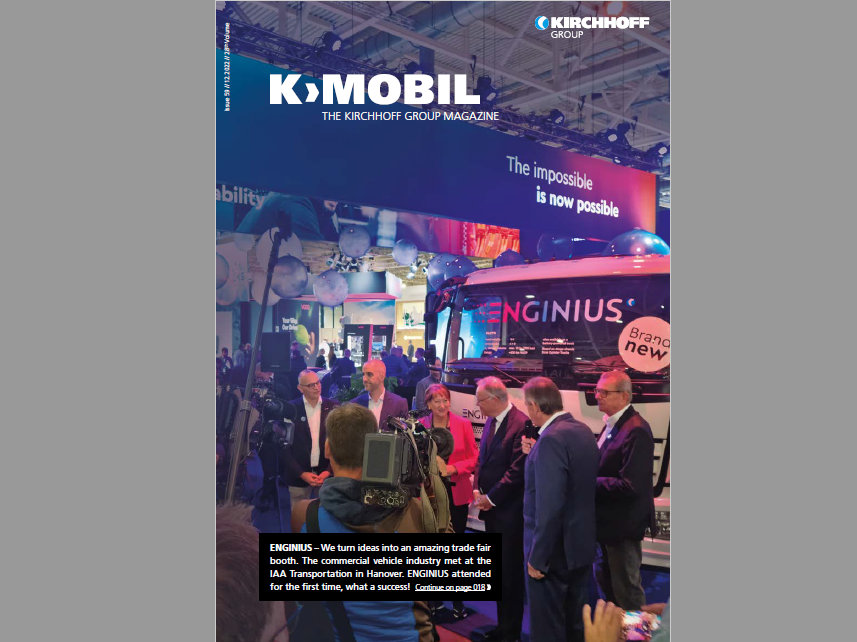

The winter issue of K>MOBIL is here!

"In view of current global challenges, it was a difficult year. Nevertheless, we believe that the companies of the KIRCHHOFF Group are well positioned for the future," says Wolfgang Kirchhoff in the lead article of the current K>MOBIL.

Which can be downloaded here.

We were all burdened by the consequences of Russia's war of aggression on Ukraine, continued bottlenecks in the supply chain and uncertainties regarding customer call-offs. On a positive note, however, we are making progress with the mobility revolution. This year, many safety-relevant metal structural parts have started production in our plants worldwide, which we have continuously developed and optimised especially for e-vehicles. At many locations, the KIRCHHOFF Group was able to expand its activities and make forward-looking investments. We report on this, as well as on the following main topics, in the current winter edition of K>MOBIL:

- Editorial: Looking back to 2022

- ENGINIUS provides climate-neutral load transport with hydrogen fuel cell-powered trucks

- Research project on inductive heating of molded blanks for press-hardened car body components

- Intelligent digitalisation with "Digital Twins“

- Trade fair appearances with new products and innovations

- The FAUN Group continues to grow and reorganize itself

The publisher of K>MOBIL, Arndt G. Kirchhoff, and the entire editorial team wish you an enjoyable read, relaxing holidays and a good start to a successful New Year.

In addition to the digital version for download, printed copies will be available from mid-December in the entrance areas and canteens, or at other central locations in our plants.

06-12-22

2022: Well Mastered Despite Difficult Circumstances

As part of the seniors’ and jubilarians’ ceremonies of KIRCHHOFF Automotive at the German sites, the shareholders J. Wolfgang and Arndt G. Kirchhoff reported retrospectively on the 2022 financial year. In view of the current challenges, they said it had been a difficult year. Nevertheless, they see the company well positioned for the future.

The consequences of Russia's war of aggression on Ukraine, continued bottlenecks in the supply chain, and uncertainties in customer call-offs were a burden. On the positive side, however, he said, was the advancing mobility revolution. "We have continuously developed and optimized safety-relevant lightweight components, especially with regard to changed car bodies and requirements for e-vehicles. This gives us confidence for the future," said CEO J. Wolfgang Kirchhoff.

Many new products and safety structural parts for e-vehicles have been successfully started up on new equipment at KIRCHHOFF Automotive's European and North American plants this year. In North America, two years of detailed research and development work on the use of Gen-3 steel resulted in the first order for a crash-relevant component made of this material. The plants in Shenyang/China and Craiova/Romania are currently undergoing extensive expansion specifically for the startup of new products for electric vehicles.

At the main plant in Iserlohn, more than 9 million euros were invested in new technologies and equipment in 2022 with the aim of producing economical and crash-relevant lightweight components for the vehicles of the future. For an aluminum underride guard, a state-of-the-art welding line based on the one-piece flow principle was put into operation in Iserlohn on an area of around 1,000 m². A second fully automated production line for the manufacture of bumpers for the BMW iX platform started volume production in June.

At the Attendorn site, more than €8 million was invested in new equipment for the electric platforms of customers VW, Audi and Mercedes-Benz as well as for plant expansions and e-charging columns in 2022. A complex production line is used to create the inner wheel arches for the two e-vehicles Audi e-tron and ID. Buzz and, in the future, for the entire VW MEB (modular e-drive system) platform. KIRCHHOFF Automotive manufactures the C-pillar for the Mercedes-Benz GLC on two new standard welding lines. The installation of another welding line for the Ford MEB platform is planned for 2023.

In the prototype shop in Attendorn, the work area was expanded by a quarter to over 3,000 m², a new double-robot spot welding system with turntable was procured, and a laser welding system was upgraded. The shipping area was also extensively expanded: finished parts are now stored on an additional 1,100 m² before being shipped to the customer.

"Thanks to our dedicated employees, who have shown great commitment and flexibility in these times, we were also able to cope very well with this year, given the circumstances," say J. Wolfgang and Arndt G. Kirchhoff.

You can read more about the 2022 financial year review and 2023 outlook in the winter edition of K>MOBIL: https://www.kirchhoff-automotive.com/deEN/media/downloads.

20-10-22

IZB: Three Successful Days for KIRCHHOFF Automotive

The largest trade fair for suppliers took place in Wolfsburg, from October 11 to 13. After a break of four years due to the coronavirus pandemic, 940 international suppliers (more than ever before) were attracted to the IZB. In Volkswagen's hometown, KIRCHHOFF Automotive also presented its latest innovations and solutions for e-mobility.

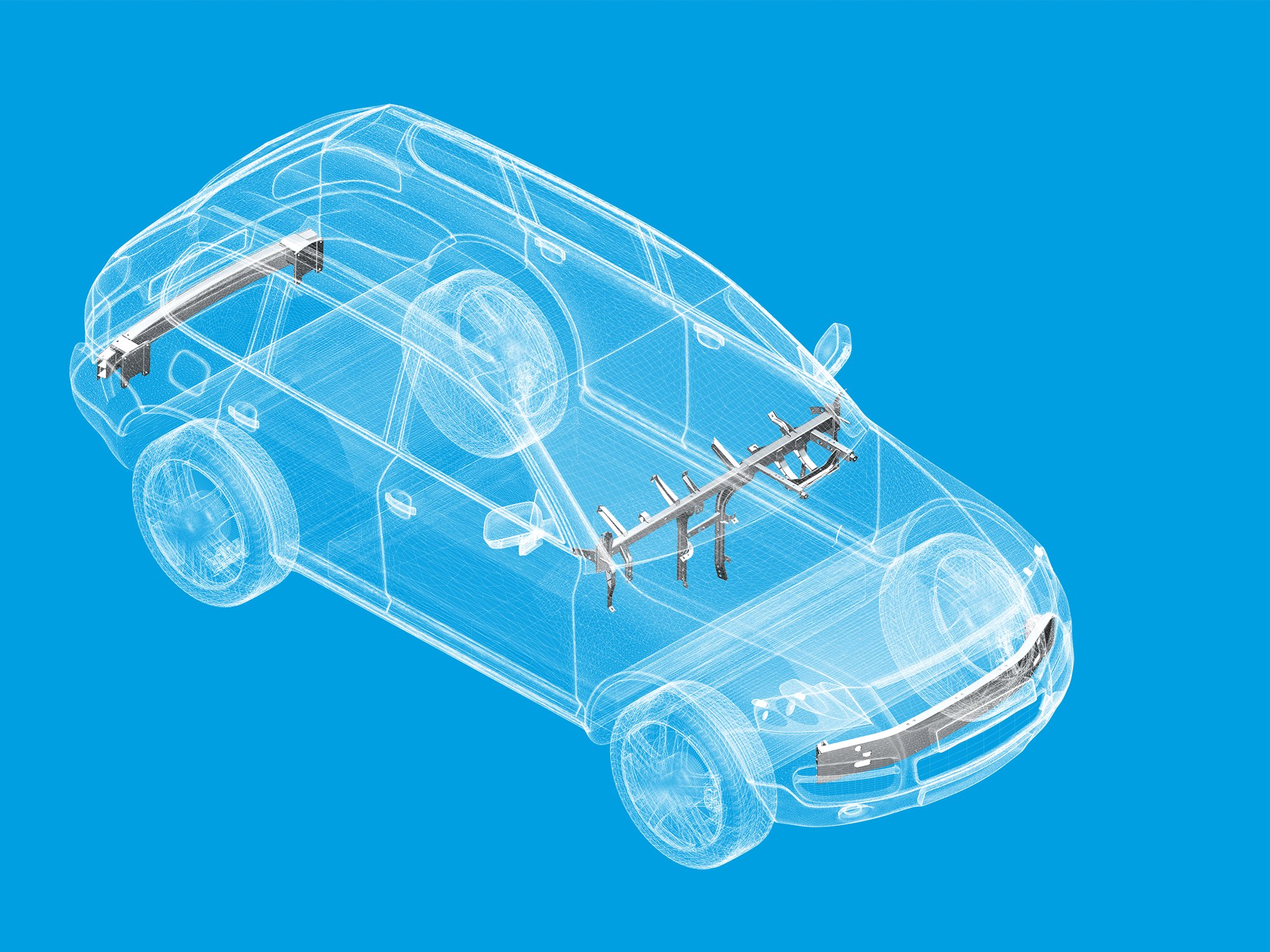

Our trade fair presence was based on the motto “MAKING.MOBILITY.SAFE.”, because our economical lightweight products ensure that even in the vehicles of the future, people are optimally protected in the event of an accident. The best example: an aluminum underride protection for the VW MEB platform. With this product, we are supplying (for the first time!) a component in series production, which, together with other components, ultimately forms the battery module and protects it.

VW has now become one of our most important customers. We supply many of our core products to VW, including various structural parts (some of them safety-relevant). These items are constructed in a lightweight design using new hot-forming grades.

Johannes Schauf, director of sales VW, was optimistic: "The discussions with our customer testified to mutual trust and common objectives. Our open booth, the way we presented ourselves, and the atmosphere we were able to create was a perfect fit."

29-09-22

A Smart Luxury Flagship SUV for Families

KIRCHHOFF Automotive also ensures safety in the new Lixiang L9. The six-seat luxury SUV is a space wonder and offers extremely comfortable space for many occupants. The L9 was officially launched on June 21, 2022.

Compared to its first model Lixiang One, Lixiang L9 offers an all-round improvement in interior space, safety, comfort and entertainment.

Lixiang L9 not only meets the highest safety standards of the C-NCAP (China-New Car Assessment Program) and the C-IASI (China-Insurance Automotive Safety Index), but also sets a higher level of safety standards for the brand: both sides of the 25% small offset crash will achieve the highest rating of G. G (“good”) represents the highest safety level in the C-IASI assessment, compared to A (“acceptable”, M (“marginal”) and P (“poor”).

KIRCHHOFF Automotive has developed all-aluminum front and rear bumpers and cross car beam for Lixiang L9. The all-aluminum bumpers not only help to lighten the body, but also effectively absorb the impact energy in the event of a front or rear collision, protecting every family member in the car as much as possible.

The Lixiang L9 replaces the traditional LCD dashboard and all physical buttons on the panel with two 15.7-inch OLED control touchscreen and a passenger entertainment touchscreen. The choice of an all-aluminum cross car beam involved thermal deformation challenges, which meant a higher level of design and manufacture capabilities for KIRCHHOFF Automotive. By constantly adjusting the position of the holes of the brackets, we were able to meet the tight tolerances required to keep the two screens safer and more secure while achieving lightweight and improved stiffness of the front structure.

The cooperation between KIRCHHOFF Automotive and Lixiang started with the first generation of the One, which has demonstrated excellent performance in the Chinese market over the past two years. This has also provided KIRCHHOFF Automotive China with increasing development experience in light-weighting and crash safety management for electric vehicle bodies. In the future, KIRCHHOFF Automotive will continue to explore the Chinese market and bring lighter and safer products to this market.

21-09-22

The truck of the future drives electrically...

and of course with body elements from KIRCHHOFF Automotive. Around 1400 exhibitors from 42 countries are presenting their innovations for transportation and logistics at the IAA Transportation in Hanover.

KIRCHHOFF Automotive will be there together with ENGINIUS, the new brand for hydrogen trucks from KIRCHHOFF Ecotec. Central topics at the world's largest mobility event are climate protection, alternative drives, digital networking and concepts for the growing delivery traffic in cities. With ENGINIUS, the KIRCHHOFF Group has an absolutely unique selling point at the trade fair. The hydrogen vehicles with fuel cells are currently the only ones with a European type approval. Around 30 waste collection vehicles are already in daily use in many cities in Germany, largely without noise and above all without emissions. The interest in the joint stand of the two largest divisions of the KIRCHHOFF Group is correspondingly high. Lower Saxony's Minister President Stephan Weil and the President of the German Association of the Automotive Industry (VDA) Hildegard Müller also visited KIRCHHOFF Automotive/ENGINIUS with many accompanying journalists.

30-08-22

Support for Startups in the Circular Economy

Until October 7, 2022, interested startups can apply for the Accelerator Program by Circular Valley. This program supports them in implementing their innovative business ideas and technologies. KIRCHHOFF Automotive is part of an extensive network that assists the startups.

"What Silicon Valley is for digitalization, Circular Valley is for the circular economy. The goal is to develop concepts for emission control and waste avoidance and recycling," explains Christoph Wagener, Vice President, Research and Product Development, at KIRCHHOFF Automotive.

The program itself runs from December 2022 to February 2023. In it, innovative startups from all over the world work together and take part in customized expert workshops and training modules. The focus is also on individual support from numerous coaches, and access to a network of over 100 partners from business and science - including KIRCHHOFF Automotive.

"In today's world, the circular economy with the goal of conserving natural resources is becoming more and more important. The goal for Germany as a high-tech location must be to take a leading position in this. Circular Valley can play a significant role in bringing together the know-how of startups, science and industry to create circular economy technologies," says Prof. Christoph Wagener.

For more information, visit https://circular-valley.org/tender_batch4