30-11-23

Clear Commitment to Sustainability and Climate Protection

KIRCHHOFF Automotive and thyssenkrupp Steel Europe (tkSE) have signed a memorandum of understanding to deepen their existing strategic partnership and reduce CO2 emissions.

Both companies have made a clear commitment to sustainability and climate protection. In order to reduce CO2 emissions in the production of metal structural parts from KIRCHHOFF Automotive, they have defined certain parameters for the supply of CO2 -reduced, modern hot-forming steels from the bluemint® Steel product family.

bluemint® Steel is a mass-balanced product with a reduced CO2 footprint. The supply of this steel to KIRCHHOFF Automotive is planned from the second half of 2026.

"By using modern, CO2-reduced steels, we are taking a further step towards more sustainability in our products. The majority of our CO2 footprint is caused by the use of the material we process. By using bluemint® steel from thyssenkrupp Steel, we will further reduce this and thus contribute to climate protection," said CEO J. Wolfgang Kirchhoff at the signing of the memorandum of understanding.

Dr. Heike Denecke-Arnold, Chief Operations Officer, thyssenkrupp Steel, added: "We are delighted to be working with our long-standing customer KIRCHHOFF Automotive to make the steel value chain even more sustainable in the future. By producing and using modern hot-forming steels with reduced CO2 intensity, we are making a contribution to an environmentally friendly future without compromising on product quality."

tkSE has already implemented initial measures to reduce CO2 emissions and offers steel products with a reduced CO2 footprint based on the use of recycled scrap in the blast furnace. With this bluemint®recycled material, around 1.35 tons (64 percent) of CO2 emissions can be saved compared to conventional hot-rolled strip.

Compared to conventional steels, there are no restrictions in terms of product properties and qualities.

Info: tkSE, based in Duisburg/Germany, is the largest German steel manufacturer. The company's core business areas are steel production and the manufacture of flat products made of quality steel as well as the provision of services in the steel sector.

28-11-23

2023: Reasonable result despite difficult conditions

J. Wolfgang Kirchhoff, Chairman of the Management Board of KIRCHHOFF Automotive, looks back on a year that was once again characterized by many challenges at the seniors and jubilarians’ celebrations of KIRCHHOFF Automotive at the German locations. Nevertheless, he believes that the South Westphalian automotive supplier is well positioned for the future.

The past year has not made doing business any easier. After sales on the automotive market in the first few months of the year gave rise to hopes of an economic recovery, the economy cooled down in the second half of the year. The availability of raw materials, trade restrictions and sanctions, as well as their impact on inflation, determine the framework conditions for the reorganization of supply chains.

While new registrations of electric cars are increasing significantly, those of combustion engines and plug-in hybrids are continuing to decline. This is a positive development for KIRCHHOFF Automotive. This is because the South Westphalian automotive supplier develops and produces safety-relevant metal structural components, especially with regard to changes in car bodies and requirements such as those found in electric vehicles. The company can therefore currently look forward to a good and balanced order situation for new business.

Many new products and safety structural parts for electric vehicles have been successfully launched this year on new systems in the European and North American KIRCHHOFF Automotive plants. The focus was on the development of resource-saving and crash-relevant structural body parts in lightweight construction for combustion engines and electric vehicles.

KIRCHHOFF Automotive continued to invest in technologies and production facilities at its plants worldwide in 2023. New 1800 and 400-ton presses and modern welding systems were installed in the North American plants. One year after the start of production, the latest KIRCHHOFF Automotive plant in Atlanta/USA was officially inaugurated in May. In order to create sufficient capacity for the production of body-in-white parts and dashboard carriers for new customer programs, the plants in Puebla, Mexico, and Querétaro are being extensively expanded. A new construction phase at the Esztergom plant in Hungary was already initiated at the end of 2022 after orders for larger and more complex assemblies were won.

Conscious of its ecological responsibility, KIRCHHOFF Automotive is using low-carbon steel for the first time. To this end, the automotive supplier is cooperating with leading steel manufacturers such as ArcelorMittal, SSAB and, more recently, ThyssenKrupp, to work together on the development of low-carbon steel for cars and trucks. "We are already seeing the first signs of success," confirms J. Wolfgang Kirchhoff.

Almost six million euros were invested in new technologies and equipment at the KIRCHHOFF Automotive main plant in Iserlohn in 2023. Welding capacities have been further expanded for newly launched products. For example, the first semi-automatic machine, an automated robot system for projection welding of fasteners, went into series production in spring. In addition, the automation and digital control of highly complex production processes was further advanced. Many new product launches for current, predominantly e-vehicle models from major car manufacturers were successfully implemented this year.

At the Attendorn plant, over eight million euros were invested in new systems for the electric platforms of major car manufacturers and for plant expansions in 2023. Four new welding systems - two semi-automatic and two fully automatic - were put into operation for the production of new, highly sophisticated products.

"Despite the persistently difficult conditions, we were able to close the year with a reasonable result," says J. Wolfgang Kirchhoff. In 2023, KIRCHHOFF Automotive will achieve a turnover of 1,800 million euros with around 8,000 employees. "The trust of our customers and the performance of our employees enabled us to achieve an extraordinary increase in sales performance, so that we expect healthy growth in the coming years as well," says J. Wolfgang Kirchhoff.

You can read more about the 2023 financial year review and 2024 outlook in the winter edition of K>MOBIL.

15-11-23

Appreciated and Awarded

Our plant in Mielec, Poland has received the Award of Appreciation from our customer Hyundai CZ.

Changki Lee, President and CEO of Hyundai Motor Manufacturing Czech, thanked the entire KIRCHHOFF Automotive project and launch team for their excellent support during the start of production for the new Hyundai Kona Sx2e model.

10-11-23

Ten years together, a winning future

On October 30, our plant in Shenyang/China celebrated its 10th anniversary. Almost 100 guests attended the celebrations in the new factory hall no. 4, including high-ranking representatives of our customers, authorities and suppliers.

In the morning, before the guests arrived, CEO J. Wolfgang Kirchhoff held a speech for the employees and thanked them.

In their speeches, the invited guest speakers emphasized the sincere appreciation, fair cooperation, rapid development and continuous innovation. "For the chassis and body parts business, we need such a strong and professional partner. In this regard, we believe that KIRCHHOFF Automotive is an excellent partner who will continue BMW's core competencies in the market and grow with us. Ten years ago, our cooperation began with crash management components for the 5 Series, which were then used in other derivatives. The 10th anniversary celebration reflects the successes of the past years for BMW / BBA and KIRCHHOFF Automotive," said Ingo Kraus, Vice President Purchasing, QMP Powertrain, High Voltage Battery, Driving Dynamics of BMW China.

The highlight of the event was all the speakers on stage placing their right hand on a tool as if to countdown, until fireworks were set off at the end of the countdown and the words of the motto "Ten Years Together, A Winning Future" appeared on the big screen.

Timeline:

- 07/2006: Foundation of KIRCHHOFF Automotive Suzhou in China

- 01/2013: Foundation of KIRCHHOFF Automotive Shenyang Plant

- 06/2014: Start of Serial Production of first CCB project for GM

- 03/2016: Completion of second shop floor in Shenyang

- 04/2016: First IATF16949 certificate for Shenyang

- 02/2017: Introduction of CNC technology in Shenyang

- 05/2017: Start of Serial Production of the first Front End project for BMW

- 02/2021: number of employees in Shenyang reaches 100

- 09/2021 Introduction of 1600 ton press in Shenyang

- 10/2021: Completion of third shop floor in Shenyang

- 03/2023: number of employees in Shenyang reaches 200

- 05/2023: start of serial production of first chassis project for BMW

- 08/2023: completion of fourth shop floor in Shenyang

16-10-23

Our 3rd Sustainability Report is Available!

Despite crises, we further strengthened our commitment to sustainability in 2022. This includes, for example, focusing on CO2 emissions reduction, both in our own business and in our supply, strengthening our social responsibility with further initiatives in health and safety, volunteering, and culture events.

The latest sustainability report is another step for our company in recognizing ESG aspects and our impact on the environment, people, and business ethics. We are measuring our sustainability performance with increasing maturity and thus we are able to better manage the topics that are significant to us and to our stakeholders”, says Anna Szklarz, Global Director CSR & Sustainability

The Sustainability Report provides a comprehensive overview of KIRCHHOFF Automotive's strategy, goals and performance in terms of governance, business ethics, environmental and social sustainability. In this third edition of our sustainability report, you will find many examples, figures, and graphs showing that we have continued to expand our activities on our way to sustainability.

You can download the current KIRCHHOFF Automotive Sustainability Report here.

06-09-23

"Now I feel safer when I'm in the car"

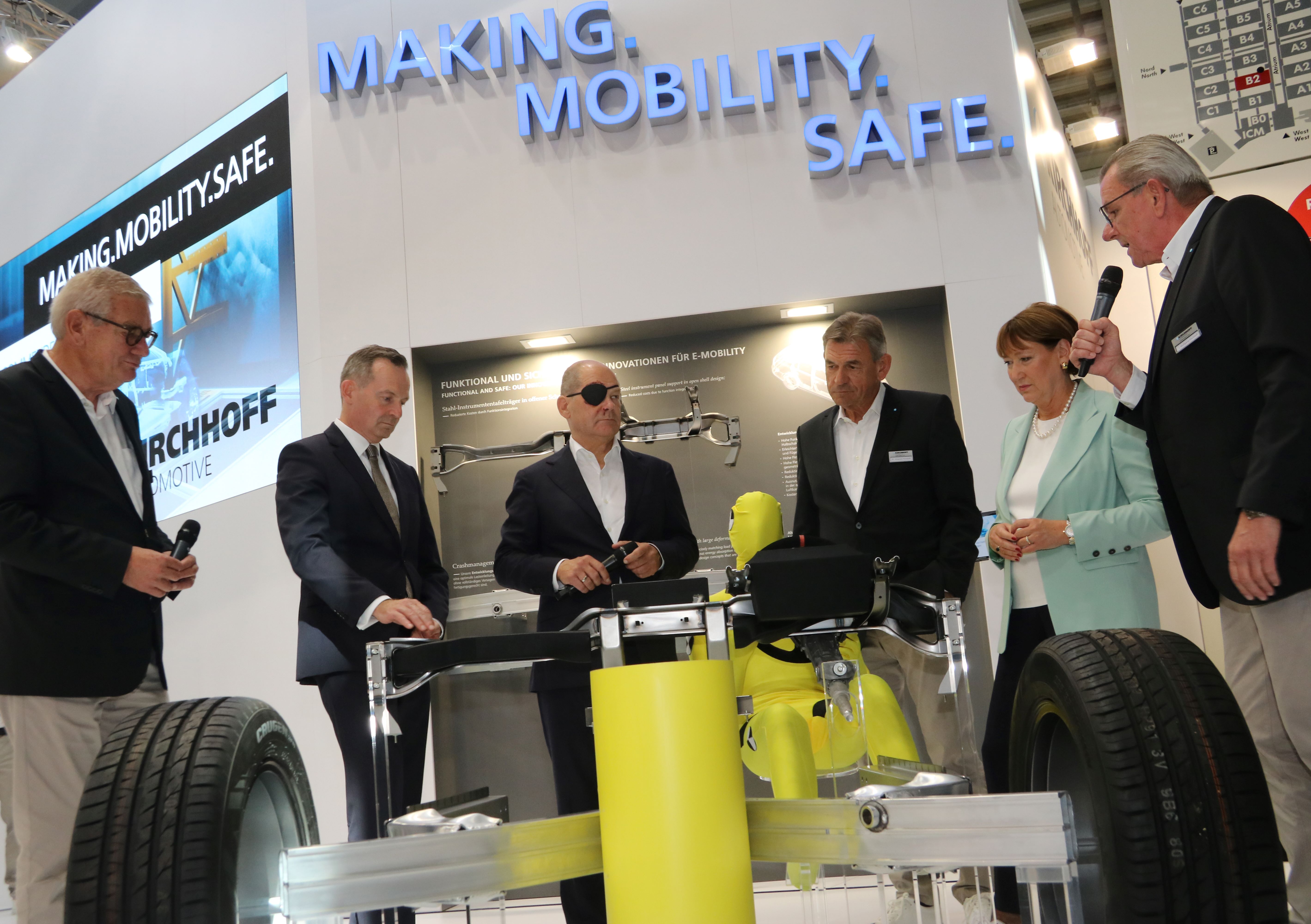

German Chancellor Olaf Scholz has visited the KIRCHHOFF Automotive booth at the IAA Mobility. CEO J. Wolfgang Kirchhoff presented him the innovative instrument panel carrier in a shell design and a crash management system with high deformation capacity.

"The mission of KIRCHHOFF Automotive is to make cars safer," CEO J. Wolfgang Kirchhoff explained to the German chancellor. Together with the German Transport Minister Volker Wissing and VDA President Hildegard Müller, he visited the trade show booth of the medium-sized company, which has been producing since the early days of the automotive industry. The delegation was informed in detail about two of the safety components developed by the company.

One of the components is an aluminum crash management system that dissipates kinetic energy through deformation. KIRCHHOFF Automotive developed the profile together with Hammerer Aluminium Industries (HAI). What makes it special are the connection points to the side member. "In the event of a crash, the system holds without a weld seam failing," explained J. Wolfgang Kirchhoff. Therefore, he said this product is a special element for vehicle safety.

Another innovation that the chancellor took a closer look at is an instrument panel beam in shell design. "Most instrument panel beams have a tubular centerpiece, which is very cost-intensive," J. Wolfgang Kirchhoff explained. In addition to cost savings, KIRCHHOFF Automotive's product has the advantage of allowing for functional integration. For example, cables or ventilation guides can be incorporated.

"Those are the two things we are demonstrating here. Otherwise, there are many things here for vehicle safety," J. Wolfgang Kirchhoff concluded. In response, the chancellor affirmed, "Thank you very much. Now I feel safer when I'm in the car.

01-09-23

This is what we present at the IAA MOBILITY

It all starts in a few days: IAA MOBILITY in Munich kicks off on September 4 with the Press and Media Day. Our team is ready: Under the mission MAKING.MOBILITY.SAFE. we present body solutions that make tomorrow's mobility safe.

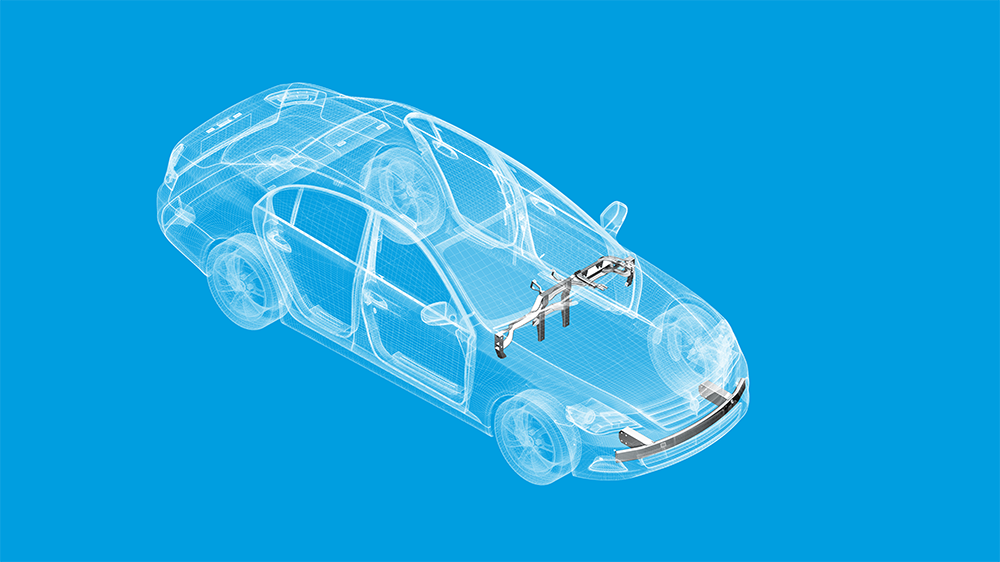

Innovative lightweight safety structural components ensure that people are optimally protected in the event of an accident. Our experts provide detailed insights into advanced solutions for safe mobility.

E-vehicle safety: crash management systems with large deformation capacity.

Our development goals include precisely matching load paths and components for optimal load application, ensuring continuous energy absorption over long intrusion paths without complete failure, and developing design concepts that are both material- and fabrication-appropriate. Here we offer two solutions: one made of aluminum and one made of steel.

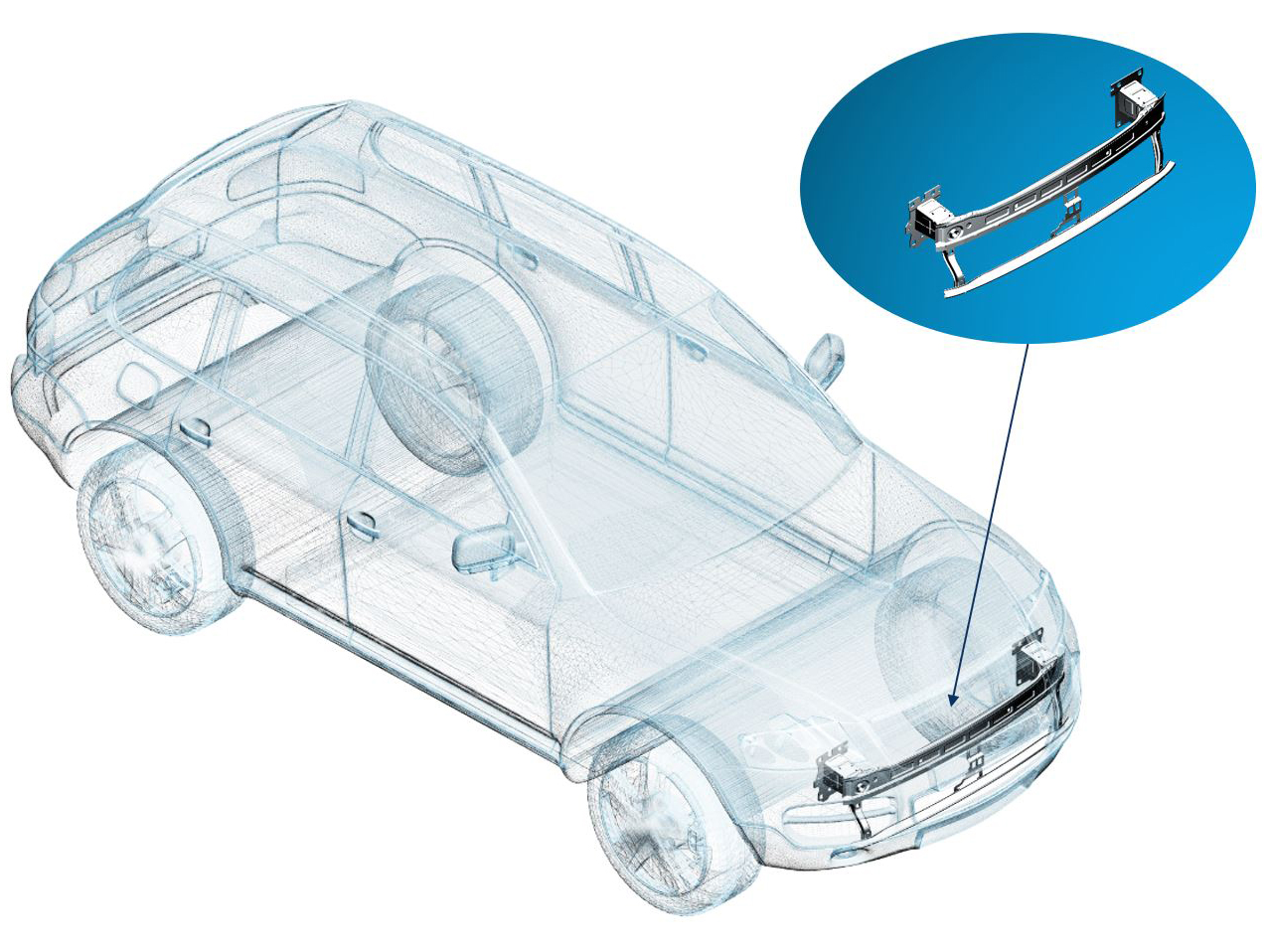

The cost-optimized solution: steel crash management system

With this concept, we can ensure a very high level of passive safety in the future and significantly increase protection against corrosion. Pre-galvanized steels were used for this purpose, whose process-safe processing poses a challenge in particular to the joining technology. In addition to a MAG welding process optimized for galvanized materials, a fully laser-welded concept was realized for the first time. The steel crash management system (CMS) enables continuous energy absorption over long intrusion paths without complete failure.

The lightweight solution: aluminum crash management system

Lightweight solutions are becoming increasingly important, especially for e-vehicles. The crash management system (CMS) we have developed in close cooperation with Hammerer Aluminium Industries (HAI) made of aluminum withstands the strong intrusions that occur in a collision and combines and high structural integrity with lightweight construction. The deformability of this crash management system without significant failure is visible in a simulated crash setup at our booth.

Functional and safe: steel instrument panel beam in open-shell design

With the newly developed instrument panel beam in open shell design, we are expanding our extensive manufacturing portfolio for this product group and creating new design options. Under the right conditions, the new design can be a means of reducing costs. Characteristics of the innovation include a high level of functional integration via the open half-shell, high flexibility in confined spaces and the reduction of weld seams and individual parts.

We will present these new developments and more at our IAA MOBILITY trade fair booth. Here we expect visits from high-ranking representatives of our customers. Our team is particularly looking forward to a visit from German Chancellor Olaf Scholz, who will find out about our innovations as part of his opening tour on September 5.

During the IAA MOBILITY, we will report regularly on our social media channels. Follow us on LinkedIn and Instagram to find our latest news!

31-07-23

The Answer to Growing Demand

Even the Hungarian Minister of Foreign Affairs and Foreign Trade, Péter Szijjártó, was impressed. He recently met with Arndt G. Kirchhoff to announce investment plans in our Hungarian plants.

In new production and logistics halls, we will manufacture body components for the electric car industry. The minister emphasized that this is of crucial importance for the growth of the economy; it is particularly important in the current difficult economic situation to decide where a company develops its capacity.

"A country that can succeed and invest in this new industry can guarantee that its economy will continue to grow in the future," the minister said. He added that KIRCHHOFF Automotive’s investment here is a "sign of confidence in the country and an indication of positive expectations for its future economic development."

Besides Germany and China, Hungary is the only country where all three German premium car brands have production capacities. Hungary is already the fourth largest producer of electric batteries in the world. "Hungary has become the European bastion of this new industry that is emerging before our eyes, and it is impossible to imagine this automotive revolution here in Europe without us," Péter Szijjártó emphasized.

The minister explained that German companies continue to represent, by far, the largest investor community in Hungary: “Around 6,000 German companies employed more than 300,000 people in Hungary, and more and more investments were coming from Germany. This shows that the confidence of German investors in Hungary is stable, it is not affected by political reasons, and that the investment climate remains attractive for German companies."

Bilateral trade between Germany and Hungary has also reached a new record, rising 12 percent last year to more than 60 billion euros. It exceeded 24 billion euros in the first four months of this year, with another record expected by the end of the year.

KIRCHHOFF Automotive is investing around 20 billion HUF (approx. 50 million euros) in new production and logistics halls in Esztergom and Dorog. This will create 80 new jobs. Series production for four customers will start in Dorog in 2024, in a modernized production and logistics hall covering 6,300 m². Two production and logistics halls with a total area of 6,200 m² will be built at the headquarters in Esztergom.

Info: In Hungary, KIRCHHOFF Automotive employs more than 700 people. KIRCHHOFF Automotive has been present here since 2004. At that time, the company began manufacturing body components exclusively for Suzuki. Since then, KIRCHHOFF Automotive has been expanding and can serve around 20 customers with its current capacity. In 2019, the Esztergom site was expanded. Having received orders for larger and more complex assemblies, KIRCHHOFF Automotive has embarked on a completely new expansion phase.

14-07-23

Saving 40% of CO2 with Emission-Free Steel

On the way to a green future, KIRCHHOFF Automotive is strengthening its cooperation with steel supplier SSAB in order to reduce CO2 in car body construction.

Steel is the main component of cold-formed body parts, such as those produced by KIRCHHOFF Automotive. When thinking of the production of this material, one often first thinks of energy-intensive blast furnaces with high CO2 emissions. However, there is another way: using the SSAB Fossil-free Steel TM, we save almost 40% in emissions in the production of a front bumper.

SSAB Fossil-free Steel TM is a steel developed by our raw material supplier SSAB. The steel is produced using a new process that uses DRI (direct-reduced iron) and does not use fossil energy. Instead, biogas and fossil-free electricity are used. The quality and properties of this material are just as good as those of steel conventionally produced by SSAB.

We recently named SSAB Supplier of the Year 2023 in the raw material category. This is the third time the Swedish-Finnish steel company has received the award. "We at SSAB are striving for a close partnership with KIRCHHOFF Automotive. We want to jointly take a leading role in the development and use of CO2 -reduced or CO2 -free steel grades in the automotive sector in the coming years," said and Roman Kaiser (sales director of SSAB Europe) at the award ceremony.

The new steel is used, for example, in the production of a front crash management system. This consists of various individual components such as crash boxes, the main beam, lower beam, and closure plate. The crash boxes, lower beam, and closure plate are produced by cold forming, and the individual parts weigh between 300g and 1.3kg.

The SSAB steel currently used for this crash management system accounts for 40% of its CO2 footprint. By changing SSAB's scope for this bumper to SSAB Fossil-free SteelTM (0.0 CO2e-emissions), its footprint will be reduced by 40%, saving approximately 585,000 kilograms of emissions per year.

“At KIRCHHOFF Automotive, we are taking the reduction of carbon emissions seriously. The partnership with SSAB allows us to further accelerate our efforts in bringing CO2-reduced solutions to our customers and on the road. In addition, it will contribute to the achievement of KIRCHHOFF Automotive’s sustainability targets”, says Michael Rank, executive vice president of procurement.

Info:

SSAB is a Nordic and US-based steel company. It offers value-added products and services developed in close collaboration with its customers to create a stronger, lighter and more sustainable world. SSAB has employees in over 50 countries and has production plants in Sweden, Finland and the USA.

For more information, visit www.ssab.com.

10-07-23

Two Anniversaries, One Success Story

KIRCHHOFF Automotive in Portugal’s plants in Ovar and Cucujães celebrated their 60th anniversary and 30 years of affiliation with KIRCHHOFF Automotive.

Time to celebrate

About 400 employees and 900 family members came to the event with their families to celebrate in summer weather, with good food and accompanied by great music and activities. On the agenda were: speeches by the Kirchhoff family and managing directors, an Excellence Award and jubilee ceremony, a “moment of talent” with a special performance by colleague Eugénio Leite (tooling technician in Ovar) who sang some songs such as the hymn of Ovar, a raffle for five KONECT program gift baskets, and a birthday cake and performance of the Tribal Samba School. On 20 tables, food and drinks were served, prepared, decorated, and managed by our employees from different departments.

"We’re thankful for being here with everyone, for wearing the KA jersey with pride, and above all, enjoying the day. The day is 100% for you!" said managing directors Hugo Ferreira and Armindo Jales.

Arndt G. Kirchhoff, chairman of the advisory board of the KIRCHHOFF Group said, “We are really happy and proud that we can be with you, my brother Wolfgang, our wives, and a big team from Germany that was able to celebrate with you. Thank you all for your day to day effort, attitude, and cooperation. We are really happy that you are here today with your families.“

CEO J. Wolfgang added, "I‘m also really happy to be here with you and really grateful that I could see the great operations that you are running here in Portugal. At the end of the day, you made it happen like a team. We have the latest technologies here in Portugal such as transfer presses, hot forming, and all kinds of latest joining technologies, such as laser welding. You are at the top of the technologies. Even better is how you are running these technologies. So once again, a big, big thank you!“

This success story began in 1963, when there was no automotive industry in Portugal. A group of Portuguese industrialists from the light metal construction sector then decided to set up a company for the production of forming tools and founded Gametal - Metalúrgica da Gandarinha, Lda on June 12, 1963. From the 1970s onwards, the company expanded its product range and also manufactured forming parts for the automotive industry.

The importance of a name

The Portuguese plants have now been part of KIRCHHOFF Automotive for 30 years - but they have only been allowed to call themselves that since 2014. While every new plant has had the word KIRCHHOFF in its name from the very beginning, the Portuguese plants were denied this until 2014. "When the international expansion of the KIRCHHOFF Group began with the acquisition of Gametal - Metalúrgica da Gandarinha, Lda, there was already a Portuguese company called "Kirchhoff Electric Repairs." According to Portuguese law, two companies cannot have the same name," explain Armindo Jales and Hugo Ferreira. "The other company then got into financial difficulties, and after some discussions we were allowed to call ourselves 100% KIRCHHOFF Automotive as of December 19, 2014."

Thanks for many years of employment

The longest-serving employee at the Portuguese plant is Jorge Ribeiro with 20 years. He was specially honored as part of the celebrations. “Congratulations and thank you for all the dedication year after year!” said the managing directors.

More honors

One of the highlights was the Excellence Award 2022 ceremony. The following employees were distinguished: Cristiano Andrade from the tool shop in Cucujães, Joana Araujo from the accounting department in Ovar, José Valente from the metrology department in Ovar, and Rosa Pinho from the welding department in Ovar. "We appreciate the effort, commitment, responsibility, ambition, and particularly, the remarkable dedication to the common goal of all of us – organizational success! We address to the nominated colleagues, their teams, and their leaders, the most sincere congratulations for the distinction received!" said the HR team.

A commemorative publication on the anniversary of the Portuguese sites can be found here: https://www.kirchhoff-automotive.com/de/medien/downloads