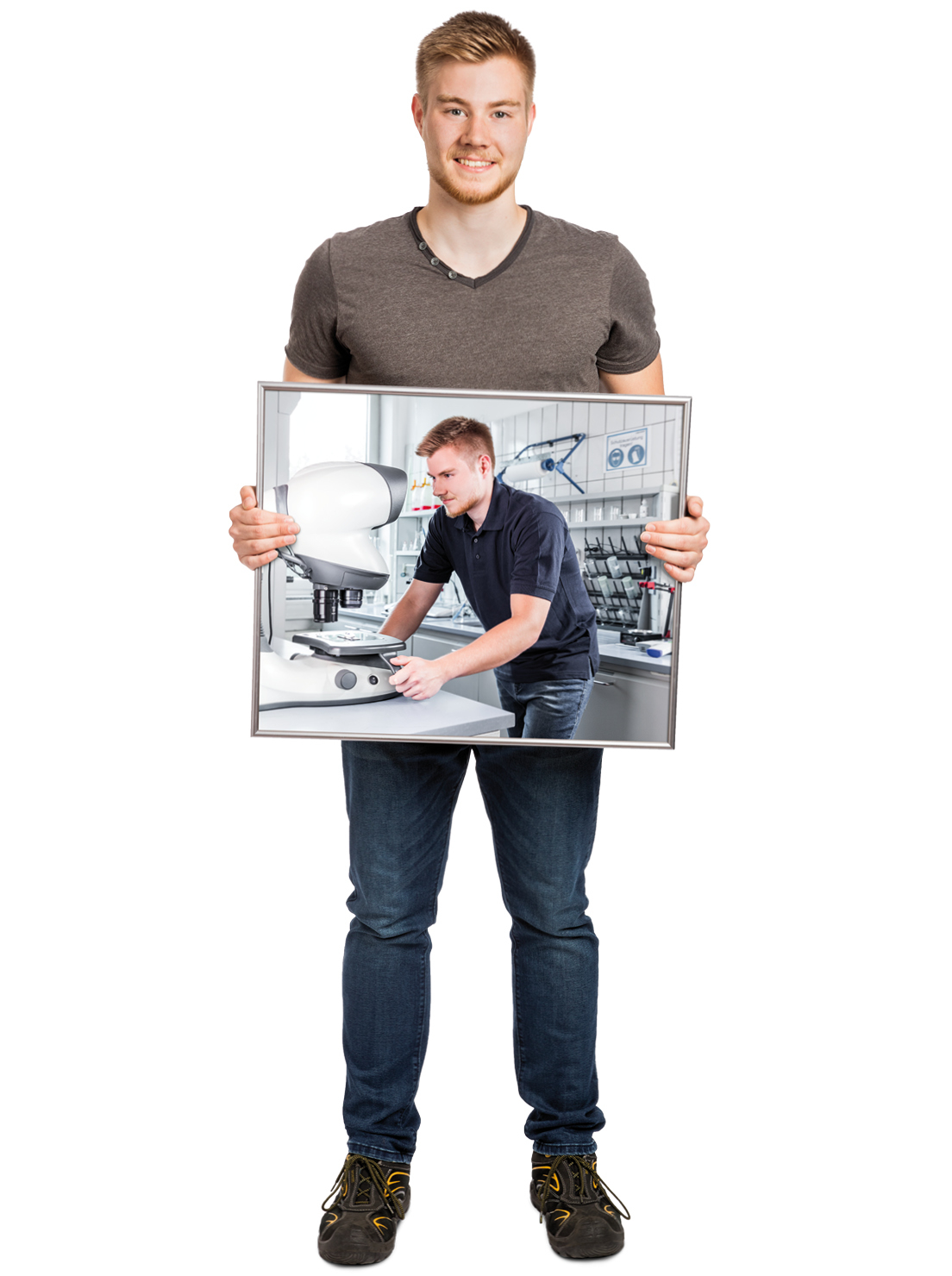

Materials tester

"In my job technical understanding, accuracy, and precision are the most important attributes – that suits me perfectly."

Lukas, Apprentice as a materials tester at our plant in Iserlohn

"As a soon-to-be materials tester I am often on the move in our production. For example I take samples of water out of the corrosion equipment and check whether the pH-value is correct. In the laboratory we carry out random checks on coated products out of the e-coat device and examine whether all values are within the tolerance range. With the microscope I am able to take a closer look at the metal. For example, welding seams can be checked more thoroughly and finally also very small cracks can be found. Many samples must be prepared at first. In order to visualize the material structure the samples will be acid-treated.

Of course I wear the corresponding protective clothing and respect the security rules in this case. Always very important is to record the test results – this is also part of my job!”

The apprentice at a glance

Job title:

Materials tester

Focus: Metall technology

Standard apprenticeship duration:

3 ½ years

We train at our plant in:

Iserlohn

Type and location of the professional school teaching:

Part time teaching in Hagen

Pre-Conditions:

General Certificate of Secondary Education, preferably Advanced Technical College Qualification

Furthermore:

- Accuracy and precision

- Technical understanding

- Responsibility

Ongoing development opportunities

After the apprenticeship as an electrician for industrial engineering you have many opportunities. Possible next steps are:

- Technician

- Academic studies

««« back to the apprenticeship overview