Development in Germany

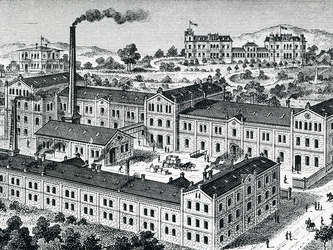

Now in its fourth generation of family ownership, the Company can look back on a long tradition in Germany. Everything started in 1785 with the founding of a needle factory in Iserlohn. Under the direction of Friedrich Kirchhoff, 100 years later, almost 2 million needles were produced on a daily basis.

On his initiative, a press and punch plant was built in the centre of Iserlohn in 1894. Nevertheless, it took until the start of the 20th century for the wagon and locomotive factories to acknowledge the advantages of pressed sheet steel parts. The mining and automotive industries soon followed.

In 1954, 170 years after its founding, needle production was finally halted and with it an economically necessary line drawn under this chapter steeped in tradition. At the end of the 1970s, the Kirchhoff family decided to dedicate all of its finances to the building of a new press shop on the outskirts of Iserlohn and thereby considerably extend its capacity for and usefulness to the automotive industry. With the acquisition of the company Matthias Kutsch in Attendorn in 1984, the focus on the automotive industry took on a new dimension. While, up until now, the plant in Iserlohn had primarily focused on the commercial vehicle industry, the supplier to passenger car manufacturers Kutsch was an ideal addition for KIRCHHOFF Automotive. The synergy with regard to expertise and equipment contributed decisively to the growth of both locations.

In order to remain competitive on the international market, an in-house R&D centre was built in 2007 in Attendorn. Here, highly-qualified engineers and technicians develop product innovations for complex components for the vehicles of worldwide automobile manufacturers.

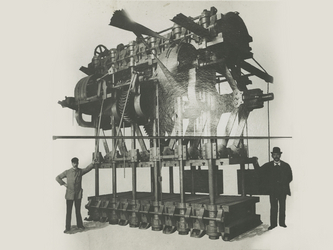

With a focus on lightweight construction, new technologies are researched and developed for series production, such as hot forming and partial hot forming. Hot-formed parts offer very high strength while being very low-weight, and are used in safety-related vehicle parts such as the passenger compartment. Since 2009, this lightweight construction technology-with the production start of a new hot forming line in Iserlohn-has become one of the core competencies of KIRCHHOFF Automotive. In order to meet customer demand, a second line, which can also produce partially tempered parts, was built two years later.