18-06-25

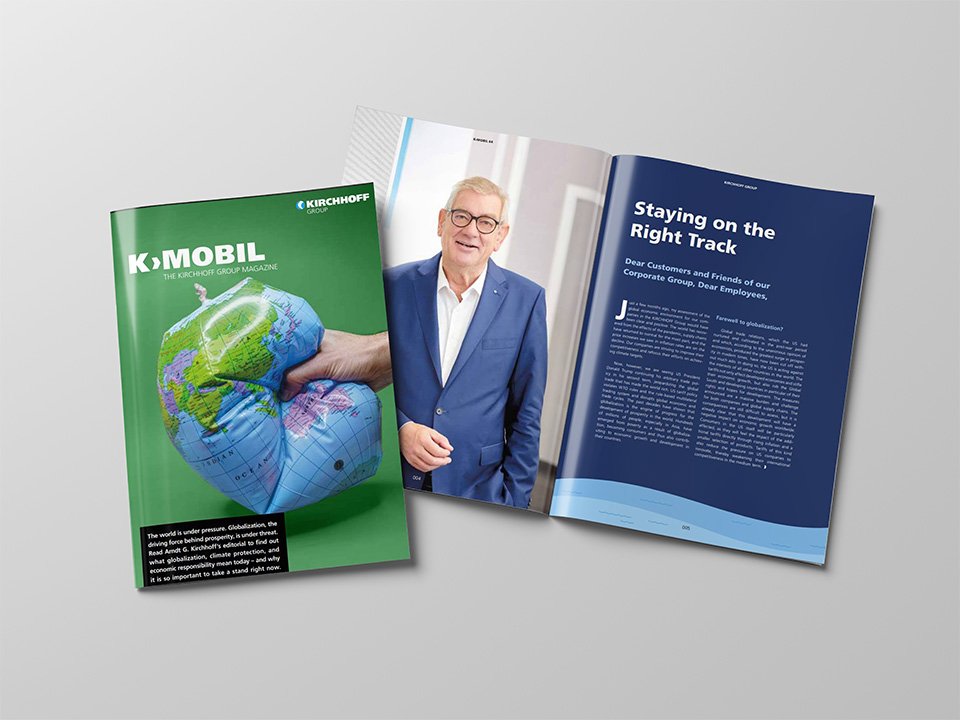

Read now: The new summer edition of K>MOBIL is here!

Globalization, partnerships, and technological innovation – these are the topics that drive us and ensure our long-term success as a company.

In the latest edition of K>MOBIL, we show how we, as the KIRCHHOFF Group, are responding to global challenges with a clear strategy, strong cooperation, and innovative solutions.

One highlight: our SIBORA steel technology, developed jointly with customers and partners and winner of the Swedish Steel Prize, enables lighter and safer vehicle structures.

Here is a brief preview of selected topics from the current issue:

- Editorial: “Staying on the right track”

- Sustainable production through innovative technologies

- SIBORA and the BQP process – award-winning!

- Trade fair reviews: Auto Shanghai & BAUMA

- Data analysis at WITTE Tools

- Special vehicles for waste collection

- Growth and new products at the ZOELLER Group

It's worth taking a look – find out more about the people, ideas, and technologies that drive our company forward.

The publisher of K>MOBIL, Arndt G. Kirchhoff, and the entire editorial team hope you enjoy reading this issue and wish you a relaxing and enjoyable summertime.

In addition to the digital version for download, printed copies will be available from mid-December in the entrance areas and canteens, or at other central locations in our plants.

13-05-25

Awarded the Swedish Steel Prize

Together with Volkswagen AG, KIRCHHOFF Automotive as SIBORA development partner has won the prestigious Swedish Steel Award 2025 for the modified BQP hot forming process and the steel grade “SIBORA”! The award was presented on May 8 in Stockholm by the Swedish steel company SSAB.

Award-winning innovation: BQP process and SIBORA

They prevailed against three strong international competitors who were also among the finalists. The jury recognized our modified hot forming process (BQP process) and the revolutionary silicon-boron steel grade “SIBORA”, which we developed in close cooperation with Volkswagen.

The innovation impressed with its outstanding properties:

- Increased safety: SIBORA material shows improved crash safety due to higher energy absorption

- Sustainability: simultaneous reduction of the body mass

- Unique material properties: High strength in the hot formed state with improved residual formability due to bainite and metastable retained austenite components

- Production-ready technology: Tests on prototypes under real production conditions have already been successful

For years, the Swedish Steel Prize has recognized outstanding engineering achievements, collaborations and steel innovations that contribute to a better and more sustainable world.

“This award impressively confirms our innovative strength and our ability to develop pioneering solutions for the automotive industry. The successful collaboration with Volkswagen and other development partners shows what is possible when leading companies pool their expertise,” commented Technology Development Senior Specialist Markus Löcker, who accepted the award on behalf of KIRCHHOFF Automotive.

Outlook

The award-winning technology opens up new possibilities for the design of lighter and at the same time safer vehicle structures. The first prototypes have already been successfully tested and we are working intensively on further optimization for series production.

The Swedish Steel Prize 2025 is a confirmation of our corporate strategy of actively shaping the mobility of the future through innovation and sustainability.

07-05-25

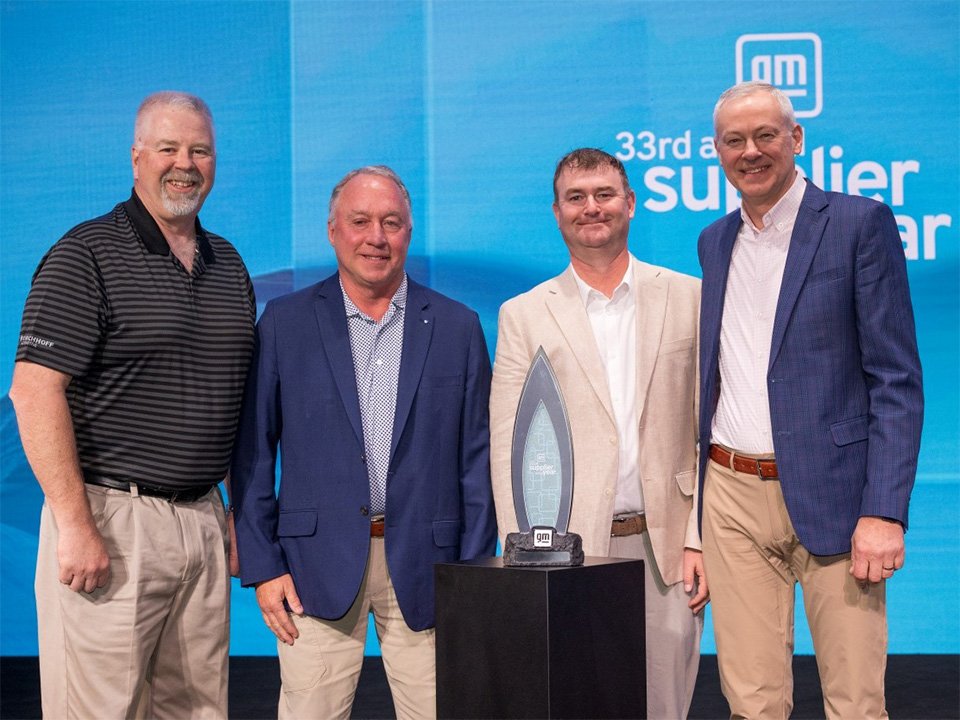

“Supplier of the Year 2024” by GM

Each year, General Motors (GM) acknowledges its most exceptional suppliers during the prestigious “Supplier of the Year” event. This year there were 92 suppliers across 12 countries recognized, including KIRCHHOFF Automotive which was proudly presented with the “Supplier of the Year 2024 in the Creativity Team of Structures” award.

Larry Hagood, President & CEO of KIRCHHOFF Automotive North America, Ken Hagle, Director of Sales, and Josh Forquer, Executive Vice President of Sales and Technical Development, accepted the award in Phoenix, Arizona, in early April. “Receiving this award in consecutive years is a great achievement for us, as it reflects our long-term commitment to meeting GM’s quality, delivery, and cost targets,” said Larry Hagood. “Since only a small fraction of GM’s global supply base receives this award, we are very proud to be among this very exclusive group and look forward to working with GM to achieve these targets in the future.”

In the selection process, GM evaluates suppliers based on their comprehensive performance throughout 2024, with a particular emphasis on alignment with GM's core values and strategic objectives. This recognition underscores our continued commitment to excellence and partnership with one of the world's prominent automotive manufacturers.

“For more than 30 years, General Motors has recognized the company’s top global suppliers at our annual event, spotlighting their innovation and resiliency through even the most challenging circumstances,” said Jeff Morrison, global chief procurement officer at GM. “Together, we’re helping bring advanced technology and the industry’s broadest portfolio of vehicles to market for GM customers.”

06-05-25

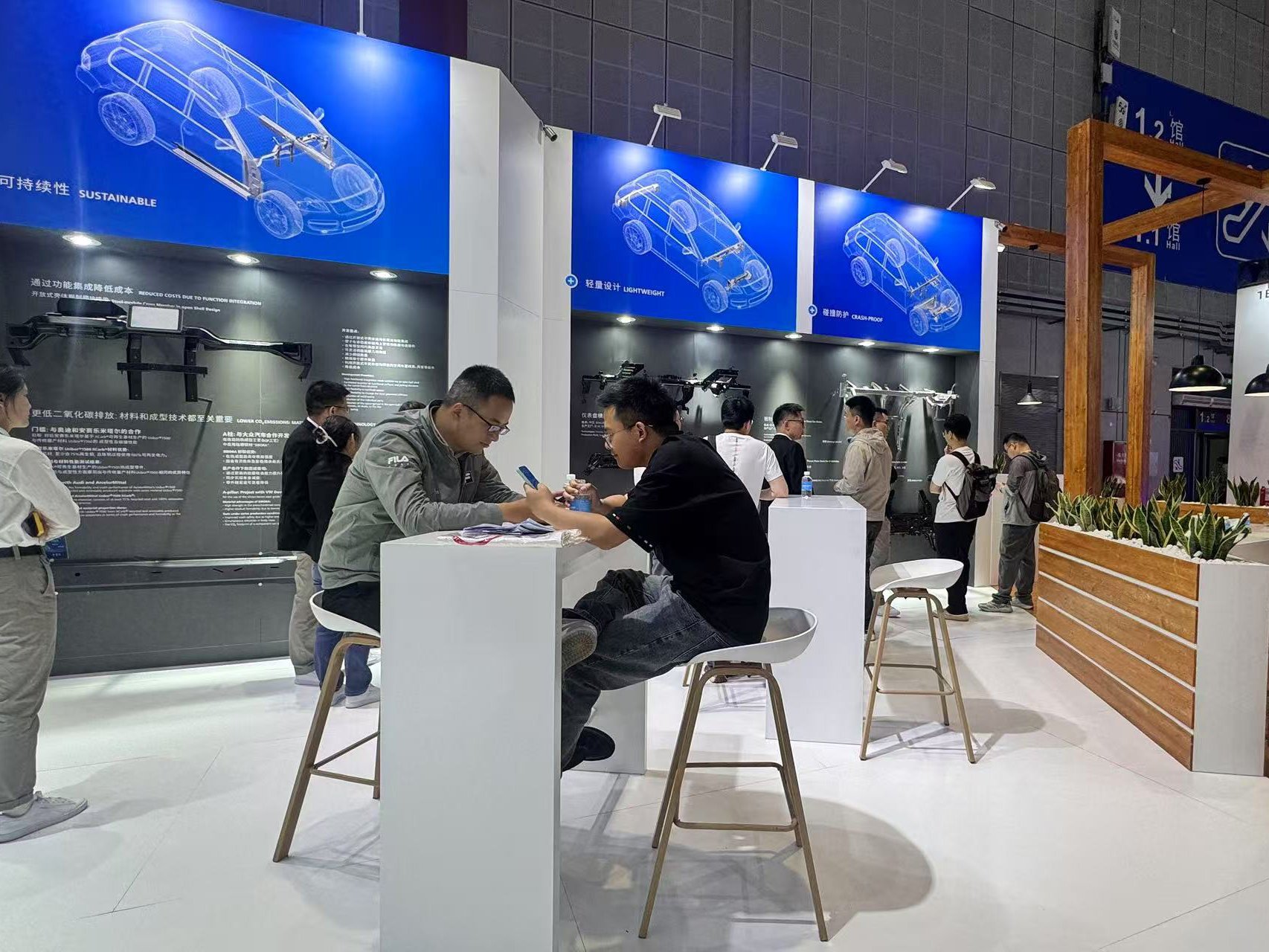

That was Auto Shanghai 2025!

Ten days full of highlights, innovations and surprises are over. “Stylish”, “innovative”, ‘influential’, “massive” - that's how our colleagues who were there describe the exhibition. Safety, artificial intelligence and connectivity are major topics for many new models.

Take a look back at the world's largest motor show in our video.

29-04-25

KIRCHHOFF Automotive presents innovative lightweight solutions at Auto Shanghai 2025

Auto Shanghai is one of the most important automotive trade fairs in the world. From April 23 to May 2, 2025, KIRCHHOFF Automotive will be exhibiting innovative body solutions and new products that will make the mobility of tomorrow safer. Visitors will find the company in Hall 1.2, Stand 1BG080.

J. Wolfgang Kirchhoff, Chairman of the Executive Board & CEO KIRCHHOFF Automotive, reports on the trade fair: "We are seeing many innovations here, especially from Chinese car manufacturers. We are also seeing a differentiation that will have an impact on the various markets in China, Europe and North America." He also observes a rising quality level of Chinese vehicles with competitive pricing.

With its latest developments, KIRCHHOFF Automotive underlines its commitment to MAKING.MOBILITY.SAFE. and its global presence. Under the motto ‘Globally present for your business’, KIRCHHOFF Automotive follows its customers into new markets and enables them to launch their products smoothly. With its comprehensive expertise in the fields of economical lightweight construction and crash performance, the global automotive supplier provides support in the development of complex metal structural parts for body and chassis. “We can produce parts for Chinese car manufacturers - both in China and in Europe,” emphasizes Dr. Thorsten Gaitzsch, Member of the Executive Board & CTO. The company operates two production plants in China and 15 in Europe, as well as 10 in North America.

Arndt G. Kirchhoff, Chairman of the Supervisory Board of the KIRCHHOFF Group, is impressed: "The progress shown by the Chinese automotive industry at this trade fair is astonishing." He particularly emphasizes the integration of communication technology and artificial intelligence. Whether this success can also be repeated in Europe or America remains to be seen - in America in particular due to the current tariffs.

J. Wolfgang Kirchhoff sees an open question in the different strategies of German car manufacturers: while some are adapting their design for Chinese customers, others are sticking to their traditional brand identity. "The crucial question is which concept will be successful on the Chinese market, which is the largest automotive market in the world," says Kirchhoff.

The KIRCHHOFF Automotive team will be presenting its latest developments at Auto Shanghai until May 2. The innovations on show include

- Components made of new silicon-boron steel grade: tests with a hot-formed B-pillar prove higher crash safety through improved energy absorption with less material usage.

- Innovative steel module cross car beam: The special open-shell design offers a high level of functional integration and contributes to cost reduction.

These solutions demonstrate how innovative materials and designs can increase crash safety while reducing weight and CO₂ emissions.

29-04-25

KIRCHHOFF Automotive presents innovative lightweight solutions at Auto Shanghai 2025

Auto Shanghai is one of the most important automotive trade fairs in the world. From April 23 to May 2, 2025, KIRCHHOFF Automotive will be exhibiting innovative body solutions and new products that will make the mobility of tomorrow safer. Visitors will find the company in Hall 1.2, Stand 1BG080.

J. Wolfgang Kirchhoff, Chairman of the Executive Board & CEO KIRCHHOFF Automotive, reports on the trade fair: "We are seeing many innovations here, especially from Chinese car manufacturers. We are also seeing a differentiation that will have an impact on the various markets in China, Europe and North America." He also observes a rising quality level of Chinese vehicles with competitive pricing.

With its latest developments, KIRCHHOFF Automotive underlines its commitment to MAKING.MOBILITY.SAFE. and its global presence. Under the motto ‘Globally present for your business’, KIRCHHOFF Automotive follows its customers into new markets and enables them to launch their products smoothly. With its comprehensive expertise in the fields of economical lightweight construction and crash performance, the global automotive supplier provides support in the development of complex metal structural parts for body and chassis. “We can produce parts for Chinese car manufacturers - both in China and in Europe,” emphasizes Dr. Thorsten Gaitzsch, Member of the Executive Board & CTO. The company operates two production plants in China and 15 in Europe, as well as 10 in North America.

Arndt G. Kirchhoff, Chairman of the Supervisory Board of the KIRCHHOFF Group, is impressed: "The progress shown by the Chinese automotive industry at this trade fair is astonishing." He particularly emphasizes the integration of communication technology and artificial intelligence. Whether this success can also be repeated in Europe or America remains to be seen - in America in particular due to the current tariffs.

J. Wolfgang Kirchhoff sees an open question in the different strategies of German car manufacturers: while some are adapting their design for Chinese customers, others are sticking to their traditional brand identity. "The crucial question is which concept will be successful on the Chinese market, which is the largest automotive market in the world," says Kirchhoff.

The KIRCHHOFF Automotive team will be presenting its latest developments at Auto Shanghai until May 2. The innovations on show include

- Components made of new silicon-boron steel grade: tests with a hot-formed B-pillar prove higher crash safety through improved energy absorption with less material usage.

- Innovative steel module cross car beam: The special open-shell design offers a high level of functional integration and contributes to cost reduction.

These solutions demonstrate how innovative materials and designs can increase crash safety while reducing weight and CO₂ emissions.

10-04-25

“Embracing Innovation, Empowering the Future”

This is the motto of Auto Shanghai, which will take place in Shanghai, China, from April 23 to May 2, 2025. There, we will be presenting new products and innovative body solutions that will make the mobility of tomorrow safer.

This trade fair is one of the most important and largest automotive trade fairs in the world and is an important meeting place for innovations and trends in the automotive industry.

Our latest lightweight products also ensure that people are optimally protected in the vehicles of the future in the event of an accident. MAKING.MOBILITY.SAFE. – is what we offer our customers worldwide with production sites in Asia, Europe and North America. Our message to our customers at Auto Shanghai is: “Globally present for your business”, because we follow our customers into new markets and enable them to launch their products smoothly. In doing so, they benefit from our comprehensive expertise in the areas of economical lightweight construction and crash performance.

We demonstrate our innovative strength with innovative new developments:

- We achieve better crash performance, less weight and lower CO2 emissions by using a new steel grade made of silicon-boron steel. Tests with a hot-formed B-pillar show higher crash safety thanks to better energy absorption and lower material usage.

- Thanks to its special open-shell design, an innovative steel module cross member offers a high level of functional integration, which helps to reduce costs.

If you would like to find out more about our innovative product developments and our global production network, you can find us at our stand: 1BG080 in hall 1.2 from April 23 to May 2.

17-12-24

The winter issue of K>MOBIL is here!

We look back on another challenging year.

Read here in the latest issue of K>MOBIL how the KIRCHHOFF Group was able to continue growing in 2024 through a high degree of adaptability and rapid action.

Sustainability remains a central topic. KIRCHHOFF Automotive has deepened its partnership with leading steel manufacturers to bring body parts made of CO2-reduced steel to series production. KIRCHHOFF Ecotec is developing advanced technologies to reduce emissions from waste collection vehicles and to promote the circular economy. With groundbreaking innovations in the production of sustainable products, we see the KIRCHHOFF Group as well positioned for the future and continue to focus on growth worldwide with investments in modern technologies. Read more about this and the following topics in this edition of K>MOBIL:

- Editorial: “In turbulent times” – a look back at 2024

- CO2 reduction: materials and forming technology are crucial

- 25 years of KIRCHHOFF Automotive in Poland: a success story

- ENGINIUS presents a new zero-emission truck for urban traffic

- FAUN and ZOELLER continue to grow

- Successful trade fair appearances with new innovative products

The publisher of K>MOBIL, Arndt G. Kirchhoff, and the entire editorial team wish you an enjoyable read, relaxing holidays and a good start to a successful new Year.

In addition to the digital version for download, printed copies will be available from mid-December in the entrance areas and canteens, or at other central locations in our plants.

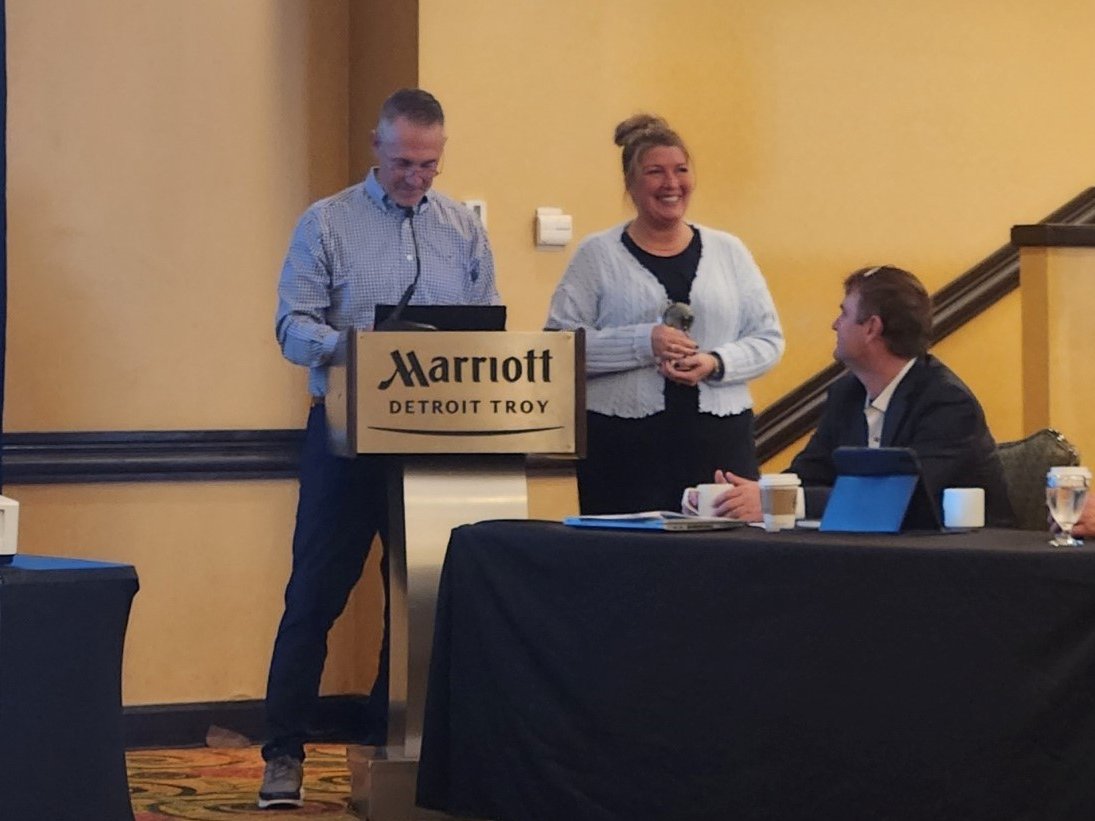

05-12-24

The Third in the Group

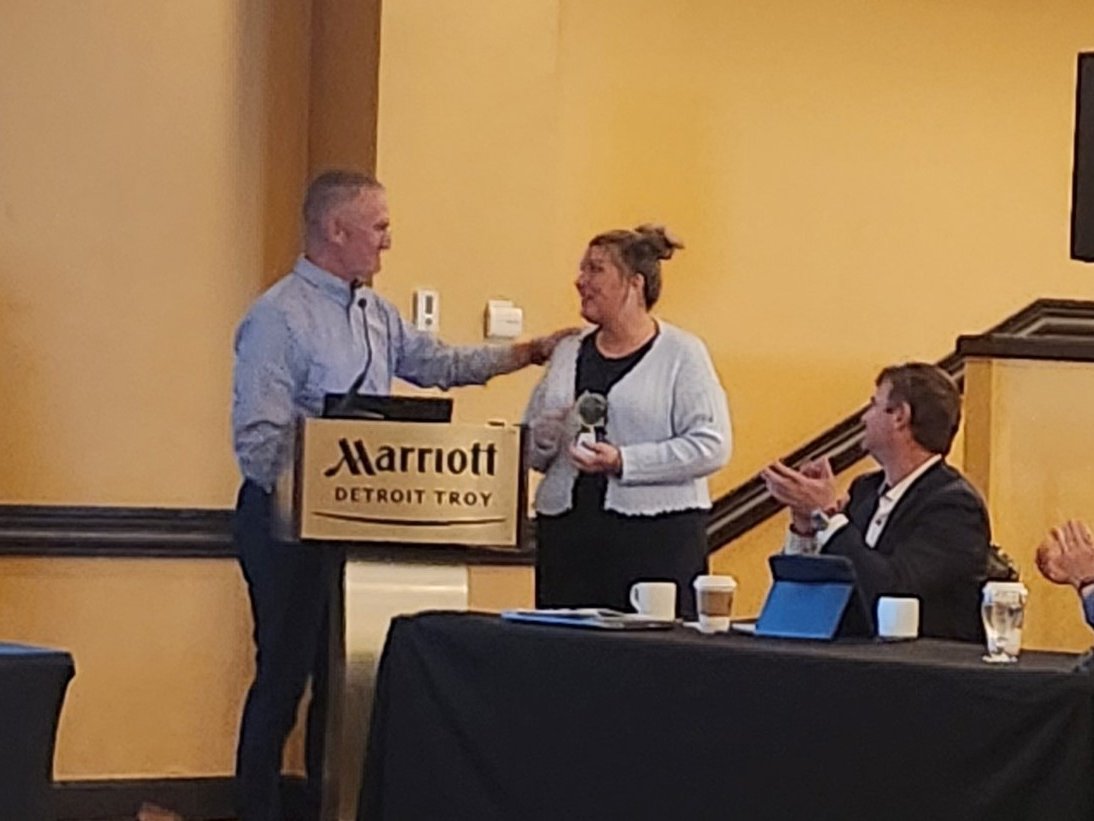

MetalForming Magazine has named Stephanie Dake, Quality Planning Specialist at our Troy location, as one of the Women of Influence in Metal Forming and Fabricating within the PMA (Precision Metal Forming Association). This makes her one of the “Women of Excellence” in metal forming, just like our colleagues Missy Smith and Susanne Ysasi.

This prestigious recognition celebrates Stephanie Dake’s outstanding contributions to the manufacturing industry over a career spanning more than two decades.

“I was thrilled and honored to have been recognized for this award,” she says. “Working in Quality can be a thankless job at times. Reading all the statements made by my peers about what ‘Stephanie’ brings to the table has really made me smile and feel appreciated.”

Stephanie's journey in manufacturing began in 1997 when she took a chance on an assembly role at KIRCHHOFF Automotive. Her initiative and capability quickly caught attention, leading to roles in quality management where she earned QS-9000 and TS-16949 certifications.

“KIRCHHOFF Automotive has provided me with a platform that allows me to make a positive influence on the quality of products we produce,” she says. “The doors are open for me to build relationships with our customers and suppliers. KA has provided me with training tools such as being certified with IATF-16949, Core quality docs, customer workshops, and more.”

Before joining KIRCHHOFF Automotive in 2017, Stephanie gained diverse experience across injection molding, stamping, and staffing industries. At our Tecumseh plant, she played a crucial role in rebuilding customer trust and resolving quality challenges.

Now at our Troy office, Stephanie leverages her shop floor experience in her Quality Planning role to advocate for production team members and share valuable insights with customers.

Reflecting on her experience, Stephanie shares wisdom for women considering manufacturing careers noting that gender diversity can lead to improved innovation, profitability, and return on equity: "Whether you're assembling or influencing the evolution of a product, our presence counts. Knowing your hands built 'that' or your 'input' changed the design/safety of that vehicle going down the road. The diverse range of opportunities, growth, benefits, wages, and most importantly work-life balance. We need more women to bring a positive impact into the manufacturing industry."

The award was presented to Stephanie at the recent KIRCHHOFF Automotive Leadership Team Meeting in Detroit. Stephanie will be featured in MetalForming's December 2024 issue, receiving special recognition and a certificate honoring her achievement.

“I am very grateful for being part of the KIRCHHOFF Automotive family for the last 8 years and looking forward to many years to come,” she says.

02-12-24

2024: Turnover maintained at previous year's level

At the anniversary celebrations at the German locations, the management of KIRCHHOFF Automotive looks back on a year with many challenges. Nevertheless, the South Westphalian automotive supplier believes it is well positioned for the future and continues to focus on growth by investing in modern technologies both locally and worldwide.

Despite a difficult market environment, KIRCHHOFF Automotive successfully maintained its position in 2024 and kept turnover at the previous year's level. While sales of electric vehicles fell significantly by 15 percent, a balanced customer mix in particular contributed to stability. “Our global orientation and the diversification of our product portfolio help us to better balance out market fluctuations,” explains J. Wolfgang Kirchhoff, Chairman of the Executive Board and CEO. With 27 production plants worldwide and over 8,500 employees, the company expects to generate sales of 1.9 billion euros in 2024.

KIRCHHOFF Automotive works closely with customers and suppliers to make CO2-reduced materials ready for series production. “90 percent of our CO2 footprint is caused by the steel and aluminum materials we use. That is why we are cooperating with leading European steel producers in the development of CO2-free or CO2-reduced steel grades,” explains J. Wolfgang Kirchhoff. By 2030, KIRCHHOFF Automotive aims to reduce direct emissions by 50 percent and use 100 percent renewable energy in all its plants worldwide.

Many new orders for larger and more complex assemblies for the major car manufacturers are again being realized at the German locations in Iserlohn, Attendorn and Saarwellingen. To this end, KIRCHHOFF Automotive has invested almost 14 million euros this year in building renovations and, above all, in modern, high-tech welding systems.

In 2024, we invested in modern technologies and new production facilities worldwide - a total of 154 million euros.

Looking at the companies in the KIRCHHOFF Group, they will be able to increase their turnover to 3.3 billion euros with 14,200 employees despite the difficult economic conditions.

You can read more about the 2024 financial year review and 2025 outlook in the winter edition of K>MOBIL that will be published on December 13.