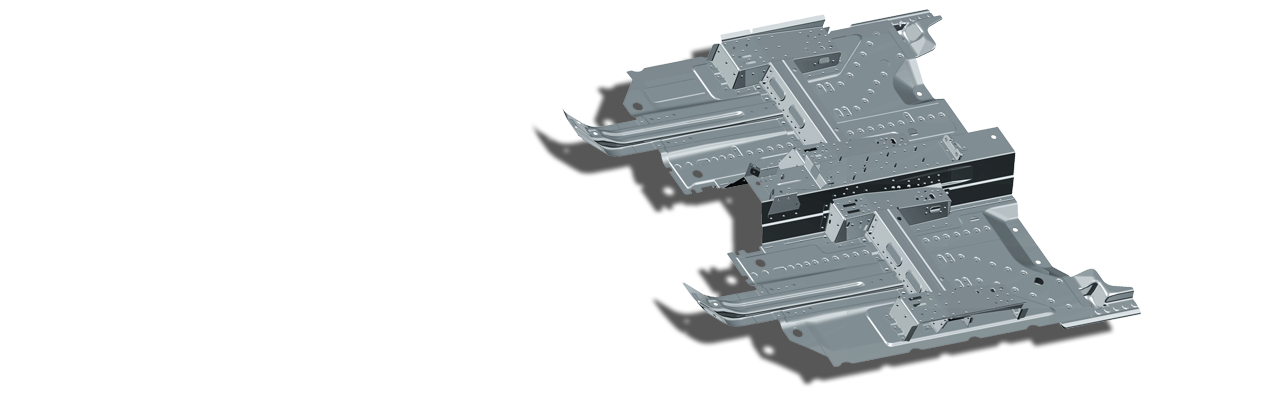

From a single part to the body-in-white structure

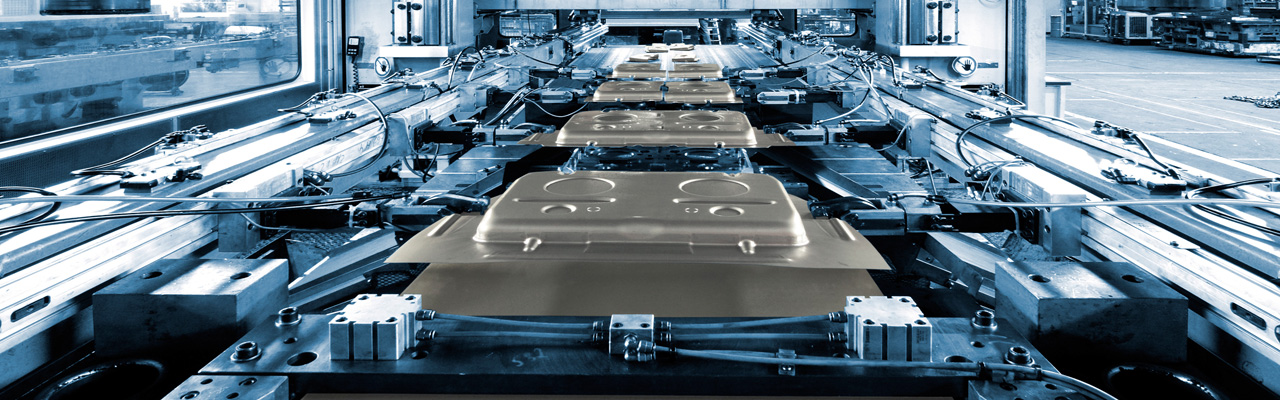

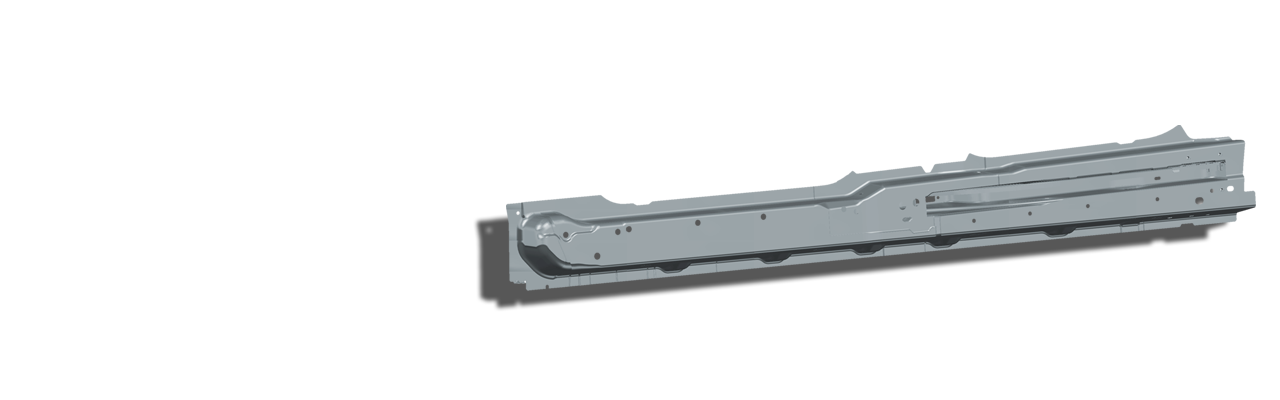

Ever since cars have existed, we have been developing, producing, and supplying metal parts—and, for the vehicles of today, hybrid structures—for the automotive industry. From a manufacturer of individual parts, we have grown into an internationally recognized development supplier of components and body-in-white structures.

KIRCHHOFF Automotive provides vehicles worldwide with extra stability and safety.

But we also offer our customers much more than that: we make a considerable contribution to the growth of their competitiveness.

The crucial cost and logistical advantages of our streamlined, medium-sized company structure with international presence serves a single purpose: to drive the market success of our customers and safeguard our innovative strength and earning power. This is our pledge worldwide.

15-12-25

Read now: The winter issue of K>MOBIL is here!

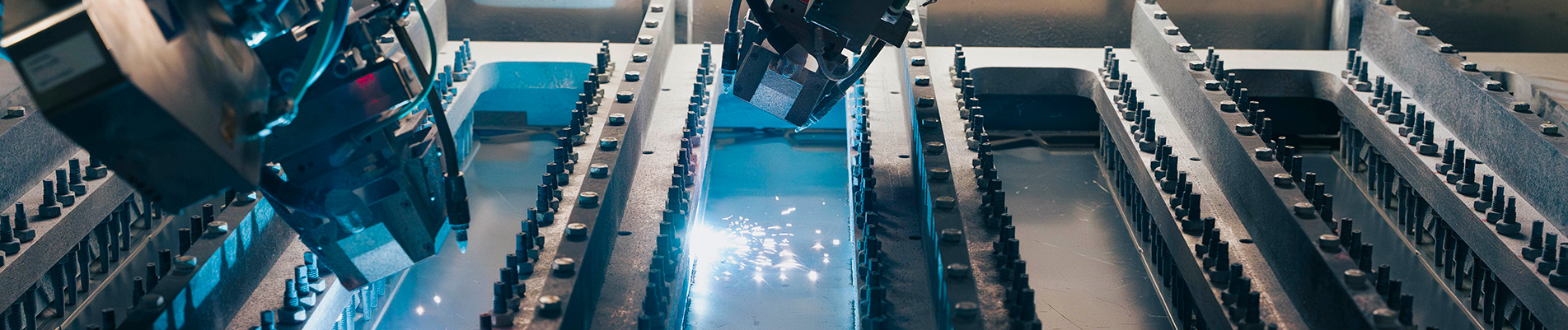

Challenges? We focus on clear strategies and innovation and continue to drive our global growth forward with investments in modern technologies and the development of sustainable products.

You can read exactly what this means in the latest issue of K>MOBIL.

The industry faces numerous challenges: strained supply chains, rising raw material and energy prices, protectionist measures, and growing demands for sustainability and digitalization.

The KIRCHHOFF Group is responding with clear strategies, sustainable technologies, and flexible procurement channels. For example, we are improving our carbon footprint with new materials for battery-electric vehicles. KIRCHHOFF Ecotec has created a new digital competence center for innovative AI solutions in waste disposal logistics.

Continuity and adaptability, high diversification in terms of customers, regions, markets, and products, as well as a stable organization and economic independence are what set us apart. We are building on this to continue growing worldwide with investments in modern technologies and sustainable products.

You can find more on this and the following exciting topics in this issue of K>MOBIL:

- Editorial: “Change and consistency” – a look back at 2025

- Compliance challenges in the automotive supply chain

- Generational change in the management of KIRCHHOFF Automotive and ZOELLER

- Successful trade fair appearances

- Awards for innovation, sustainability, and operational excellence

The publisher of K>MOBIL, Arndt G. Kirchhoff, and the entire editorial team wish you enjoyable reading, relaxing holidays, and a good start to a successful new year.

Here, you can download K>MOBIL.