26-02-21

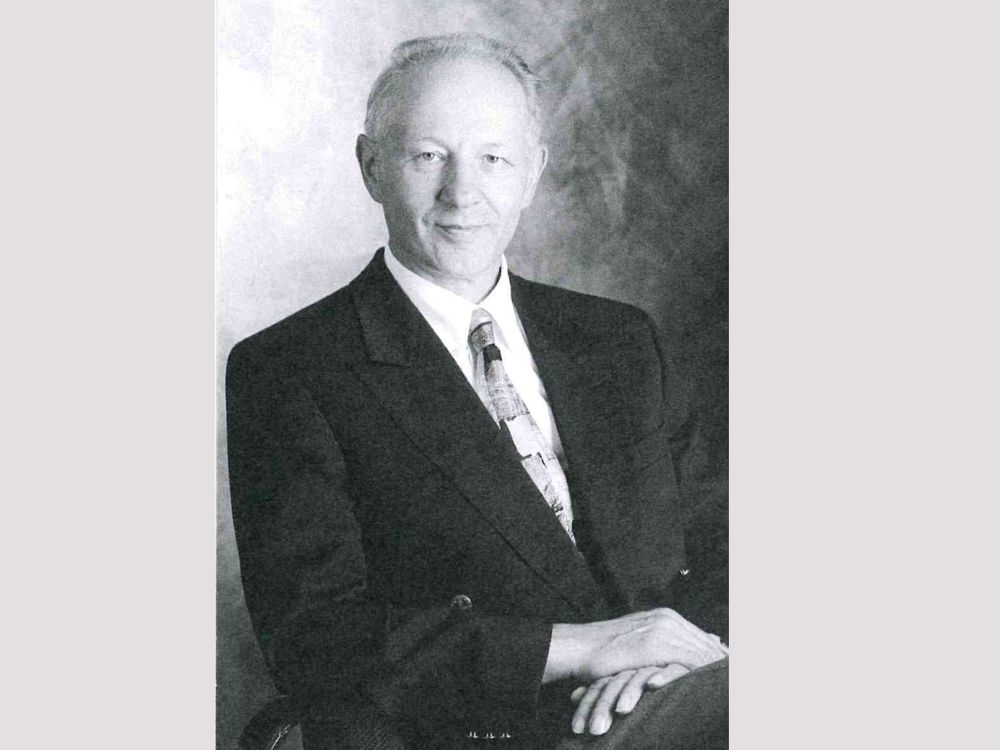

Obituary Josef Groß

We mourn the death of our former managing director Mr. Dipl.- Ing. Josef Groß who passed away on February 16, 2021 at the age of 85.

After his apprenticeship and journeyman's time as a toolmaker in Wilhelmshaven and engineering studies in Berlin, Josef Groß worked for Olympia in Wilhelmshaven and Keiper-Recaro in Remscheid and Rockenhausen.

From 1986 until his retirement in 2000, Josef Groß was Managing Director of the former M. Kutsch GmbH in Attendorn. He was also responsible for the management of Sigro in Olpe and Letterkenny in Ireland and Gametal in Portugal, which were part of the group of companies at that time. We also remember his trips to Brazil and Mexico, during which he laid the foundations for our activities in Central and South America together with Wolfgang and Arndt G. Kirchhoff. Particularly close to Josef Groß's heart were our market entry plans in the Central Eastern European countries after the fall of the Berlin Wall.

The decision to set up our plants in Poland and the composition of the management team, many of whom are still actively with us today, was certainly a highlight of his professional life.

With his decisions and many capabilities, Josef Groß had a decisive influence on the development of the entire KIRCHHOFF Group. His work in the details of forming products and processes as well as the development of the necessary joining techniques formed the solid foundation on which we were able to build our now global company. For health reasons, he handed over the operational activities from the management to his successor, Stefan Leitzgen, in 1999.

His economic, technical and human perceptiveness distinguished him and made him a valued superior and colleague.

We will remember Josef Groß with honor.

Our sincere sympathy goes to his family.

21-09-20

Office Management: 100% Digital

Digitization is becoming more and more common in KAPS Administration. With the help of digital platforms, we have introduced a new method for Office Management (OM) in our KAPS tools. This also takes continuous improvement into account.

In administration, we often use spreadsheet programs to document and analyze information. They allow rapid visualization, easy management and documentation of data history.

Now, like in production, a so-called dashboard gives an overview of all relevant key indicators at a glance in the administrative area. The dashboard is used to quickly check which indicators lie outside our goals and where we can improve performance.

„Digital Office Management is an excellent tool that alllows us to perform the OM meetings in a practical and efficient way,” says Procurement Manager Jorge Brandão. “We can now resume our team meetings that were interrupted by the pandemic.”

The OM boards previously used personal meetings, but are now replaced by this new digital format, and meetings are done via BlueJeans software. “I think that also after the pandemic we will continue to use digital Office Management, in conjunction with personal meetings,” says Armindo Jales, Managing Director Adminstration and Finance Manager.

22-07-20

A Win for Our Company

On June 25th, Subaru of Indiana Automotive (SIA) in the USA, announced their supplier award winners. There are 260 suppliers for SIA overall but KIRCHHOFF Automotive was amongst the chosen group of suppliers to receive an award.

The North York plant in Canada who produces for SIA, has been recognized with 2 category awards from Subaru this year for their hard work. They were recipients of the Excellent Performance Award, and the Commodity Leader Award.

Taken from the press release statement by Subaru: “Our success relies on a network of suppliers that provide us quality parts in a safe and timely manner,” said Scott Brand, executive vice president at SIA. “These companies represent an incredible commitment to helping Subaru efficiently manufacture high-quality vehicles for our customers.”

Winners were recognized in the following five categories:

- Special Recognition – Above and beyond effort as identified by SIA management

- Commodity Leader – Top scoring supplier in commodity category

- Excellent Performance – Achievement of SIA targets for safety, quality, cost and delivery

- Superior Excellent Performance – Three and four consecutive years as recipient of the Excellent Performance Award

- Presidential – Five consecutive years as recipient of the Excellent Performance Award

Due to COVID-19, ceremonies to honour the winners have been post-poned till later this year and plaques were delivered via mail to locations.

15-05-20

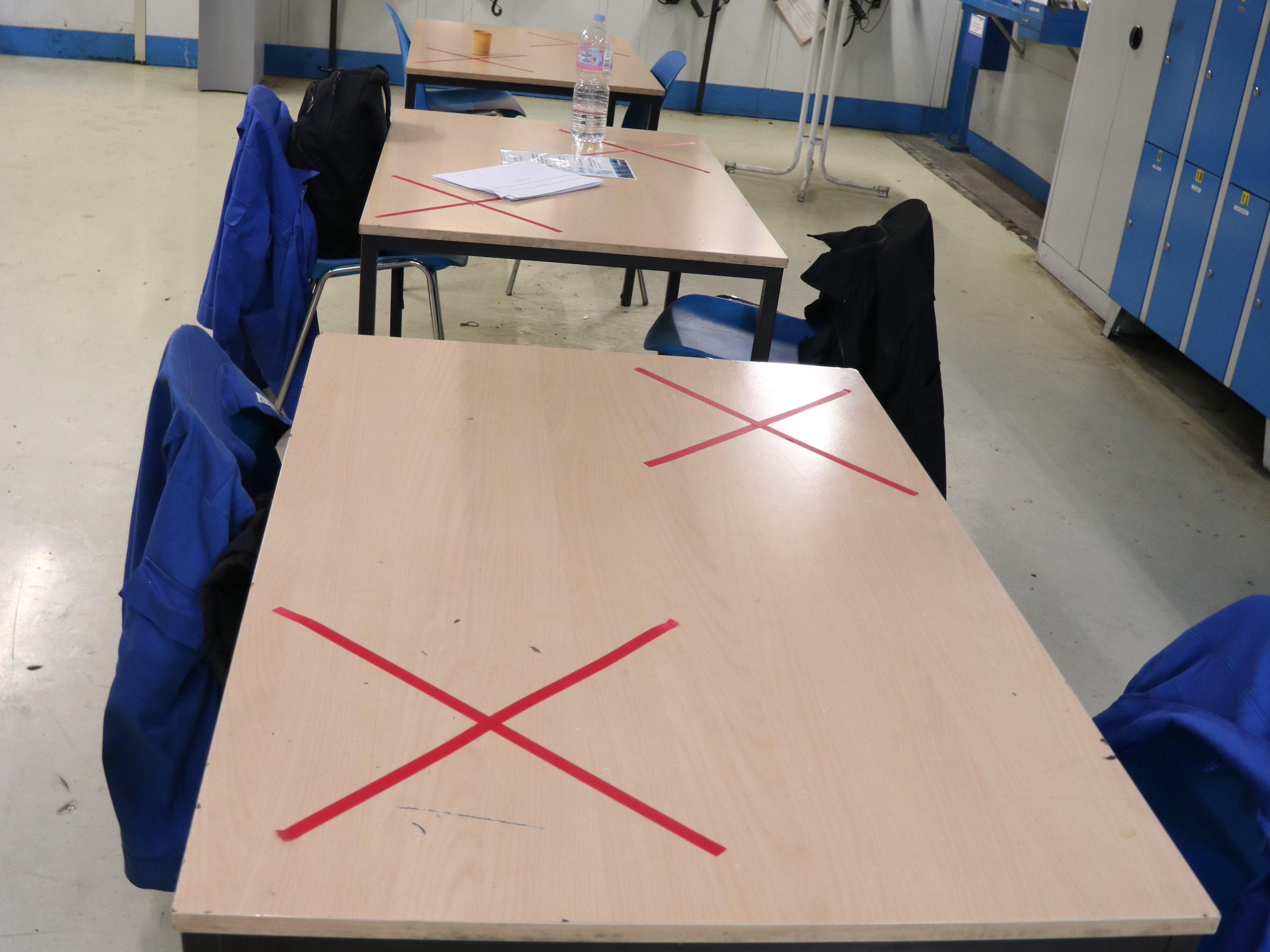

The New Normal

The face mask is put on and the hands are freshly disinfected: The workday can begin. This is what everyday life now looks like for many employees. To protect themselves and others from infection with the corona virus, we have introduced new protective measures at our plants. How do our employees deal with them?

Erik Proháska, shift supervisor press shop in Esztergom/Hungary, says: "At first the measures were difficult to get used to, but now the workers take them for granted. What the colleagues liked best was that our company took protective measures such as the use of disinfectants immediately after the outbreak of the virus".

Teams have been partly split up, so that half of them work on site at the plant and the other half in the home office, alternating weekly. Other protective measures include keeping a distance, leaving doors open, regular cleaning of frequently touched surfaces and physical barriers such as Plexiglas walls.

"I have temporarily been in the home office since March," says Sabine Montenbruck, assistant to Production Manager in Iserlohn/Germany. "Working from home works very well. I am grateful that we have this opportunity and that IT was able to equip us with laptops so quickly. At my first meeting in the office, wearing the face mask was still a bit unusual. By the second visit, it was almost routine."

Mike Walsh, Health, Safety & Environmental Manager at Aurora Corporate/Canada, explains: “Corporate and local procurement staff have been working hard to secure purchases of masks, including reusable and disposable masks, hand sanitizer, and cleaning supplies. Each facility has reviewed its inventories and are prepared for return to operations. All employees will be provided with masks should they be required to use them where we cannot provide sufficient physical distancing for the tasks they perform, government mandated, or in case employees want to wear voluntarily.”

"Some employees still have difficulty maintaining the necessary safety distance, especially at the gatehouses and the time clocks," says Fábio Valente, Health and Safety Technician in Ovar/ Portugal. Proof of disinfection of the workplaces before each shift or machine use is also a challenge, he says. In general, however, the protective measures are well accepted by the employees. "To prevent the spread of Covid-19 in our company, everyone must show responsibility. That's the message we must send to everyone."

Hugo Ferreira, Global Director KAPS in Ovar/Portugal, still works from home. "For my department, the biggest challenge is that we are not allowed to travel and hold workshops on site. That's why we do them online. Otherwise, the changeover is not dramatic for us. We are used to working in different places. So we had already established management systems to coordinate our teams."

"Wearing the masks, disinfecting hands and surfaces became very easy habits. Sometimes we forget to take off the masks, for example when we drink a glass of water or just eat a snack - they have already become a part of us," says Corina Mandă, Management Assistant in Craiova/Romania.

Thomas Lozinski, Head of Hot Forming & Trailer Systems at the Iserlohn/Germany plant is optimistic: "We don't let our work spoil the fun and make the best of the situation. We know that KIRCHHOFF Automotive is well positioned and that we will survive this difficult time. You can feel the fighting spirit in the workforce and the willingness to help overcome the crisis. The community and cohesion in the company are important pillars for all employees and provide security.

We all have to get used to this new normal. In order to protect ourselves and others, the measures will probably remain in place for quite some time. But we are confident that by doing so, we can all contribute to the safe working conditions in our factories.

04-05-20

Slow RESTART

With limited production, we will restart our plants in Europe and North America in the coming weeks. COO Stefan Leitzgen with an overview of the current status and what we can expect in the coming weeks.

Andreas Heine: What is the timetable for Europe, when will which plant start up again?

Stefan Leitzgen: The first plants restarted last week, others will follow this week and the last hopefully from 11 May. However, we often work in single shifts at the beginning and not even on all plants and over the whole week. For example, we will start in Attendorn this week on a shift with 25 employees, normally about 120.

Andreas Heine: They say that the development in North America is a good two weeks behind. Does that also apply to the restart in Canada, USA and Mexico?

Stefan Leitzgen: In general, that is the case. The complete lock down in all three countries will continue until at least May 10th, in Mexico even until the end of the month. But even these dates change almost daily. With very few exceptions, none of our customers are planning to restart before 11 May.

Andreas Heine: How much of our capacity will the customers call up? Are the strategies for ramping up the automotive plants similar or completely different?

Stefan Leitzgen: We expect a maximum of 50% of normal sales in Europe in May, and that is already an optimistic scenario. In North America, we expect sales to be significantly lower. Basically, all OEMs are planning similarly. They all start with one shift and then increase their production week by week. Often the assembly lines run slower than before the crisis because fewer employees are used. The speed of ramp-up varies from manufacturer to manufacturer.

Andreas Heine: Are we well prepared for the restart everywhere or are there still special challenges?

Stefan Leitzgen: All plants must carry out a "Return to Work" audit. This is how we check whether all Covid19 precautionary measures have been implemented. And every employee worldwide receives training in which the plant-specific measures are explained. Yes, I am convinced we are very well prepared.

Andreas Heine: Will our new binding instructions for dealing with each other in the plant be accepted in times of Corona and will they be implemented where employees are already working?

Stefan Leitzgen: Our Covid19 protective measures will also be implemented in the plants where employees are already working. Of course not everything is running smoothly yet, but it is working. There is occasional criticism, for example for the closure of the changing rooms. But there are also employees who have thanked us for our prudent approach.

Andreas Heine: Are there any projections as to how badly the shutdown has affected us as a company and what impact it will have on our annual results?

Stefan Leitzgen: There is an initial forecast for the period from January to the end of June. The figures are very sobering. However, it is still far too early to make a forecast for the entire year. But one thing is already completely clear today: we will have to tighten our belts considerably.

Andreas Heine: At present it is difficult to bear the many crisis reports every day. Is there anything that could cheer us up a bit, give us hope for the future?

Stefan Leitzgen: Yes, our management colleague in Romania has become a father for the third time.

Andreas Heine: That are definitely good news, congratulations from me as well.

04-03-20

Our Plant in Gniezno is Growing

Last year, our plant in Gniezno, Poland, was considerably expanded in only six months at a cost of just under EUR 2.7 million. We manufacture products for various VW models at this location.

The production hall for complex assemblies and logistics was expanded by 2,350 m². The expanded welding area mainly accommodates spot and MAG welding systems. The total hall area is thus 7,100 m²; if the loading road (a 17 m wide roof for loading and unloading the trucks) is added, the total area is even 8,400 m².

The office space has also been expanded. New changing rooms, an open-plan office and a new, flexibly usable meeting room have been created on 420 m².

The Gniezno location was newly established in 2015. The geographical location close to the VW plants Września and Poznan as well as the attractive job market were the decisive criteria for this decision.

20-02-20

"So beautifully quiet"

FAUN welcomed MEP and Vice-President of the European People's Party (EPP) David McAllister on Monday 17.02.2020 at the plant in Heilshorn. The MEP met with the FAUN management, the Mayor of Osterholzer Torsten Rohde and District Administrator Bernd Lütjen as well as former District Director Hans-Dieter von Friedrichs to discuss strategies for the expansion of the hydrogen infrastructure to enable energy supply for emission-free heavy-duty traffic.

After the test drive with the ROTOPRESS BLUEPOWER, FAUN's refuse collection vehicle powered by hydrogen fuel cells, McAllister said: "So nice and quiet. FAUN has developed the battery hydrogen drive system ready for series production and is building 22 of these emission-free vehicles this year. The basis is a Mercedes Benz Econic as a glider, in which battery packs, fuel cells and hydrogen tanks are installed instead of the combustion engine and exhaust system. The vehicles will be assembled according to the area of application. Hydrogen is an ideal carrier, the medium is light and has a high density, so that longer operating times are no problem.

For FAUN hydrogen is the only reasonable drive system. Only in this way is a closed energy cycle possible. With the BLUEPOWER vehicles, FAUN provides companies with one hundred percent electric and emission-free refuse collection vehicles and sweepers. Noise emissions are also marginal, as all units have been optimized for quiet and energy-efficient operation. The electrical energy produced by the fuel cells from hydrogen is not only used for driving, but also for all body functions.

Domestic waste collection is stopped frequently, in densely populated areas every few meters. With conventional chassis, a lot of energy is converted into heat that cannot be used any further at the brakes, and BLUEPOWER vehicles store this energy in the batteries for later use. This means that a BLUEPOWER vehicle requires up to 40% less energy, is CO2 and NOx-free, and emits less particulate matter. FAUN is thus making a valuable contribution to the hot topic of climate protection.

Picture: Looking to the future, (from left): Matthias Kohlmann (CFO FAUN Group and President of the Stade Chamber of Commerce and Industry in the Elbe Weser region), Torsten Rohde (Mayor Osterholz-Scharmbeck), Thorsten Baumeister (COO FAUN Group), Bernd Lütjen (District Administrator Osterholz), Hans-Dieter von Friedrichs (District Director a.D.), Burkard Oppmann (Managing Director FAUN Services GmbH), David McAllister, Dr. Johannes F. Kirchhoff (Managing Partner KIRCHHOFF Group), Patrick Hermanspann (CEO FAUN Group)

10-02-20

First Strokes are done

Shortly before Christmas, the new 16,000 kN servo transfer press at our plant in Tecumseh/US started trial operation with a blank loader. The next step will be the trial run with conveyor system.

The press is the first servo transfer press of our company in North America, which can produce both over blanks and over a conveyor belt system. This provides greater flexibility for the use of this state-of-the-art press technology. In particular, the efficient use of materials was an important decision criterion here.

The press was delivered in September, and the first strokes could still be carried out in December. In addition to the relocation of a large number of forming tools to the new servo transfer press, the focus is now on employee training.

21-01-20

Commemoration of Dr. Jochen F. Kirchhoff

In a solemn memorial service on January 17, 2020, 900 people filled the churches of Oberste Stadtkirche and Bauernkirche in Iserlohn to bid farewell to Dr.-Ing. Jochen F. Kirchhoff, who passed away on December 18, 2019, at the age of 92. More than 200 managers and employees of our company also attended the event.

The main memorial service held in the Oberste Stadtkirche church was broadcasted live on a screen to the Bauernkirche church. At both locations, the ceremonies were well attended. Not only employees of the two German plants in Attendorn and Iserlohn attended the memorial service, but also colleagues from many European plants. Apart from employees, there were guests from society, politics, culture, and representatives of the North Rhine-Westphalia German state government and the presidents of the German Employers' and Metalworkers' Associations.

The life of Dr.-Ing. Jochen F. Kirchhoff was marked by creativity, humor, sportsmanship, love of music, people, and especially love for his family. It was fitting then that his family arranged the memorial service for him. Music was one of his greatest passions. Outstanding artists such as the Folkwang Kammerorchester Essen orchestra, guitarist Dale Kavanagh, violinist Moritz Ter Nedden and the Märkische Motettenkreis Iserlohn choir, performed works by Johann Sebastian Bach, Felix Mendelssohn-Bartholdy, and Samuel Barber. Pastor Jürgen Löprich delivered the sermon at the memorial service, Dr. Johannes F. Kirchhoff delivered the personal address of the family, and the grandchildren gave their own statements for their grandfather.

After the ceremony, the Kirchhoff family held a reception at the Schauburg hall in Iserlohn. A series of pictures shown at the reception, exhibited numerous impressions from the private and professional life of Dr.-Ing. Jochen F. Kirchhoff.

On the day of the memorial service, a minute of silence was held for Dr.-Ing. Jochen F. Kirchhoff in many places across the company.