01-09-23

This is what we present at the IAA MOBILITY

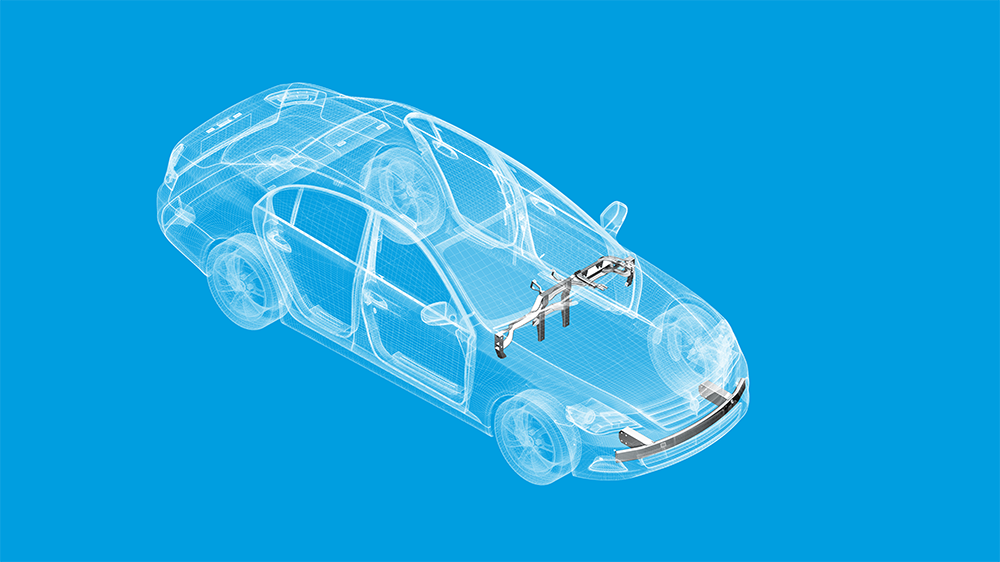

It all starts in a few days: IAA MOBILITY in Munich kicks off on September 4 with the Press and Media Day. Our team is ready: Under the mission MAKING.MOBILITY.SAFE. we present body solutions that make tomorrow's mobility safe.

Innovative lightweight safety structural components ensure that people are optimally protected in the event of an accident. Our experts provide detailed insights into advanced solutions for safe mobility.

E-vehicle safety: crash management systems with large deformation capacity.

Our development goals include precisely matching load paths and components for optimal load application, ensuring continuous energy absorption over long intrusion paths without complete failure, and developing design concepts that are both material- and fabrication-appropriate. Here we offer two solutions: one made of aluminum and one made of steel.

The cost-optimized solution: steel crash management system

With this concept, we can ensure a very high level of passive safety in the future and significantly increase protection against corrosion. Pre-galvanized steels were used for this purpose, whose process-safe processing poses a challenge in particular to the joining technology. In addition to a MAG welding process optimized for galvanized materials, a fully laser-welded concept was realized for the first time. The steel crash management system (CMS) enables continuous energy absorption over long intrusion paths without complete failure.

The lightweight solution: aluminum crash management system

Lightweight solutions are becoming increasingly important, especially for e-vehicles. The crash management system (CMS) we have developed in close cooperation with Hammerer Aluminium Industries (HAI) made of aluminum withstands the strong intrusions that occur in a collision and combines and high structural integrity with lightweight construction. The deformability of this crash management system without significant failure is visible in a simulated crash setup at our booth.

Functional and safe: steel instrument panel beam in open-shell design

With the newly developed instrument panel beam in open shell design, we are expanding our extensive manufacturing portfolio for this product group and creating new design options. Under the right conditions, the new design can be a means of reducing costs. Characteristics of the innovation include a high level of functional integration via the open half-shell, high flexibility in confined spaces and the reduction of weld seams and individual parts.

We will present these new developments and more at our IAA MOBILITY trade fair booth. Here we expect visits from high-ranking representatives of our customers. Our team is particularly looking forward to a visit from German Chancellor Olaf Scholz, who will find out about our innovations as part of his opening tour on September 5.

During the IAA MOBILITY, we will report regularly on our social media channels. Follow us on LinkedIn and Instagram to find our latest news!