14-07-23

Saving 40% of CO2 with Emission-Free Steel

On the way to a green future, KIRCHHOFF Automotive is strengthening its cooperation with steel supplier SSAB in order to reduce CO2 in car body construction.

Steel is the main component of cold-formed body parts, such as those produced by KIRCHHOFF Automotive. When thinking of the production of this material, one often first thinks of energy-intensive blast furnaces with high CO2 emissions. However, there is another way: using the SSAB Fossil-free Steel TM, we save almost 40% in emissions in the production of a front bumper.

SSAB Fossil-free Steel TM is a steel developed by our raw material supplier SSAB. The steel is produced using a new process that uses DRI (direct-reduced iron) and does not use fossil energy. Instead, biogas and fossil-free electricity are used. The quality and properties of this material are just as good as those of steel conventionally produced by SSAB.

We recently named SSAB Supplier of the Year 2023 in the raw material category. This is the third time the Swedish-Finnish steel company has received the award. "We at SSAB are striving for a close partnership with KIRCHHOFF Automotive. We want to jointly take a leading role in the development and use of CO2 -reduced or CO2 -free steel grades in the automotive sector in the coming years," said and Roman Kaiser (sales director of SSAB Europe) at the award ceremony.

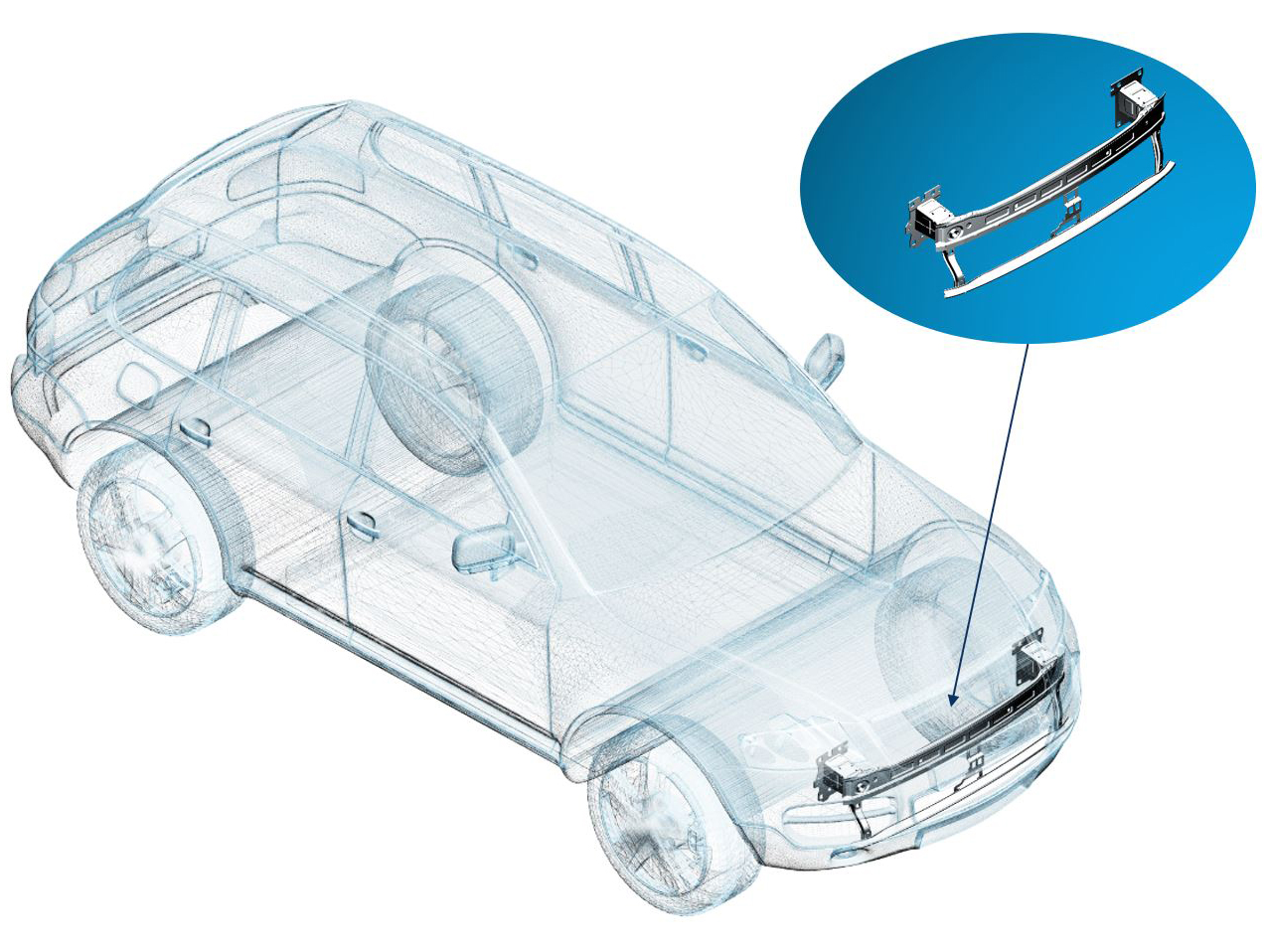

The new steel is used, for example, in the production of a front crash management system. This consists of various individual components such as crash boxes, the main beam, lower beam, and closure plate. The crash boxes, lower beam, and closure plate are produced by cold forming, and the individual parts weigh between 300g and 1.3kg.

The SSAB steel currently used for this crash management system accounts for 40% of its CO2 footprint. By changing SSAB's scope for this bumper to SSAB Fossil-free SteelTM (0.0 CO2e-emissions), its footprint will be reduced by 40%, saving approximately 585,000 kilograms of emissions per year.

“At KIRCHHOFF Automotive, we are taking the reduction of carbon emissions seriously. The partnership with SSAB allows us to further accelerate our efforts in bringing CO2-reduced solutions to our customers and on the road. In addition, it will contribute to the achievement of KIRCHHOFF Automotive’s sustainability targets”, says Michael Rank, executive vice president of procurement.

Info:

SSAB is a Nordic and US-based steel company. It offers value-added products and services developed in close collaboration with its customers to create a stronger, lighter and more sustainable world. SSAB has employees in over 50 countries and has production plants in Sweden, Finland and the USA.

For more information, visit www.ssab.com.