06-09-23

"Now I feel safer when I'm in the car"

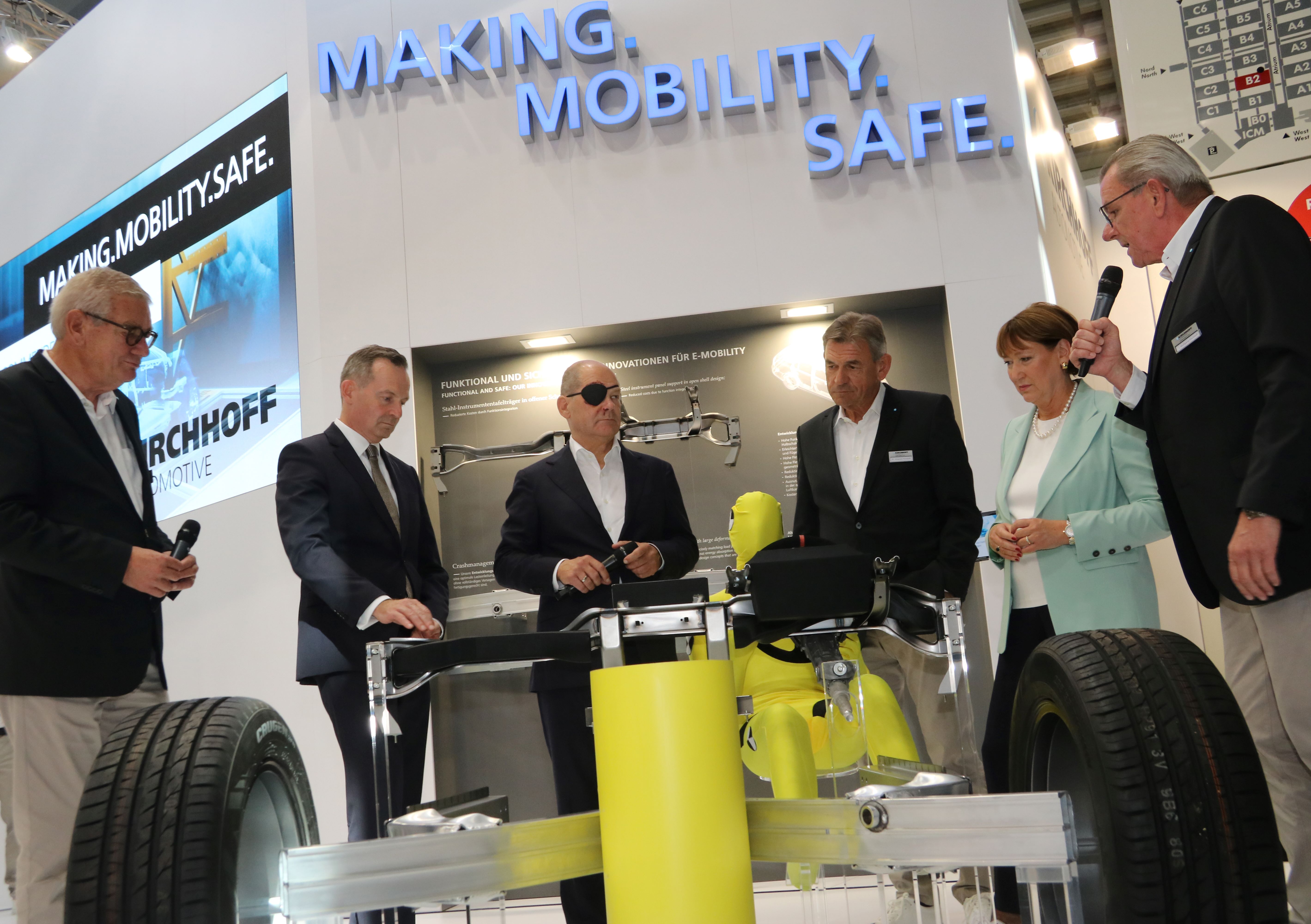

German Chancellor Olaf Scholz has visited the KIRCHHOFF Automotive booth at the IAA Mobility. CEO J. Wolfgang Kirchhoff presented him the innovative instrument panel carrier in a shell design and a crash management system with high deformation capacity.

"The mission of KIRCHHOFF Automotive is to make cars safer," CEO J. Wolfgang Kirchhoff explained to the German chancellor. Together with the German Transport Minister Volker Wissing and VDA President Hildegard Müller, he visited the trade show booth of the medium-sized company, which has been producing since the early days of the automotive industry. The delegation was informed in detail about two of the safety components developed by the company.

One of the components is an aluminum crash management system that dissipates kinetic energy through deformation. KIRCHHOFF Automotive developed the profile together with Hammerer Aluminium Industries (HAI). What makes it special are the connection points to the side member. "In the event of a crash, the system holds without a weld seam failing," explained J. Wolfgang Kirchhoff. Therefore, he said this product is a special element for vehicle safety.

Another innovation that the chancellor took a closer look at is an instrument panel beam in shell design. "Most instrument panel beams have a tubular centerpiece, which is very cost-intensive," J. Wolfgang Kirchhoff explained. In addition to cost savings, KIRCHHOFF Automotive's product has the advantage of allowing for functional integration. For example, cables or ventilation guides can be incorporated.

"Those are the two things we are demonstrating here. Otherwise, there are many things here for vehicle safety," J. Wolfgang Kirchhoff concluded. In response, the chancellor affirmed, "Thank you very much. Now I feel safer when I'm in the car.

01-09-23

This is what we present at the IAA MOBILITY

It all starts in a few days: IAA MOBILITY in Munich kicks off on September 4 with the Press and Media Day. Our team is ready: Under the mission MAKING.MOBILITY.SAFE. we present body solutions that make tomorrow's mobility safe.

Innovative lightweight safety structural components ensure that people are optimally protected in the event of an accident. Our experts provide detailed insights into advanced solutions for safe mobility.

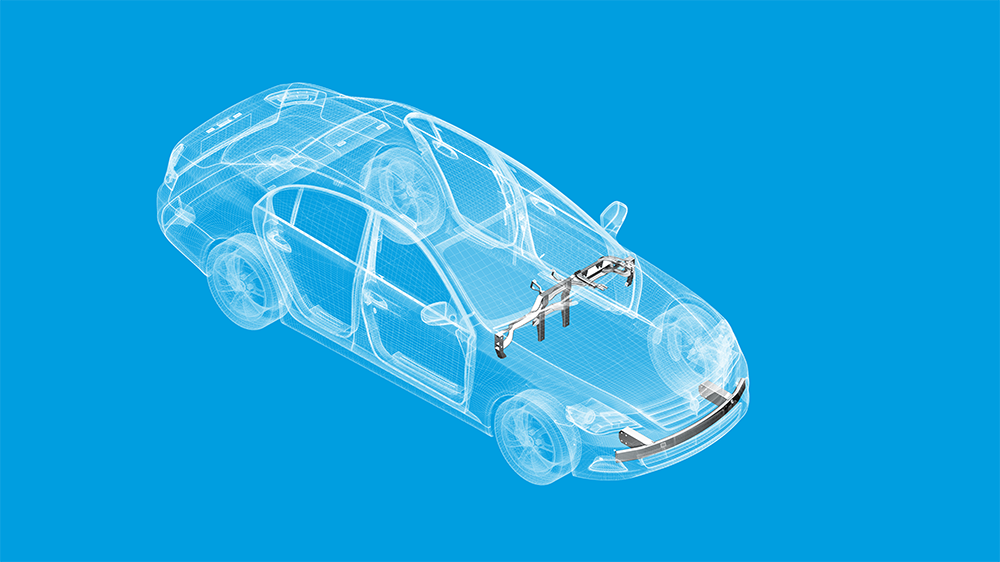

E-vehicle safety: crash management systems with large deformation capacity.

Our development goals include precisely matching load paths and components for optimal load application, ensuring continuous energy absorption over long intrusion paths without complete failure, and developing design concepts that are both material- and fabrication-appropriate. Here we offer two solutions: one made of aluminum and one made of steel.

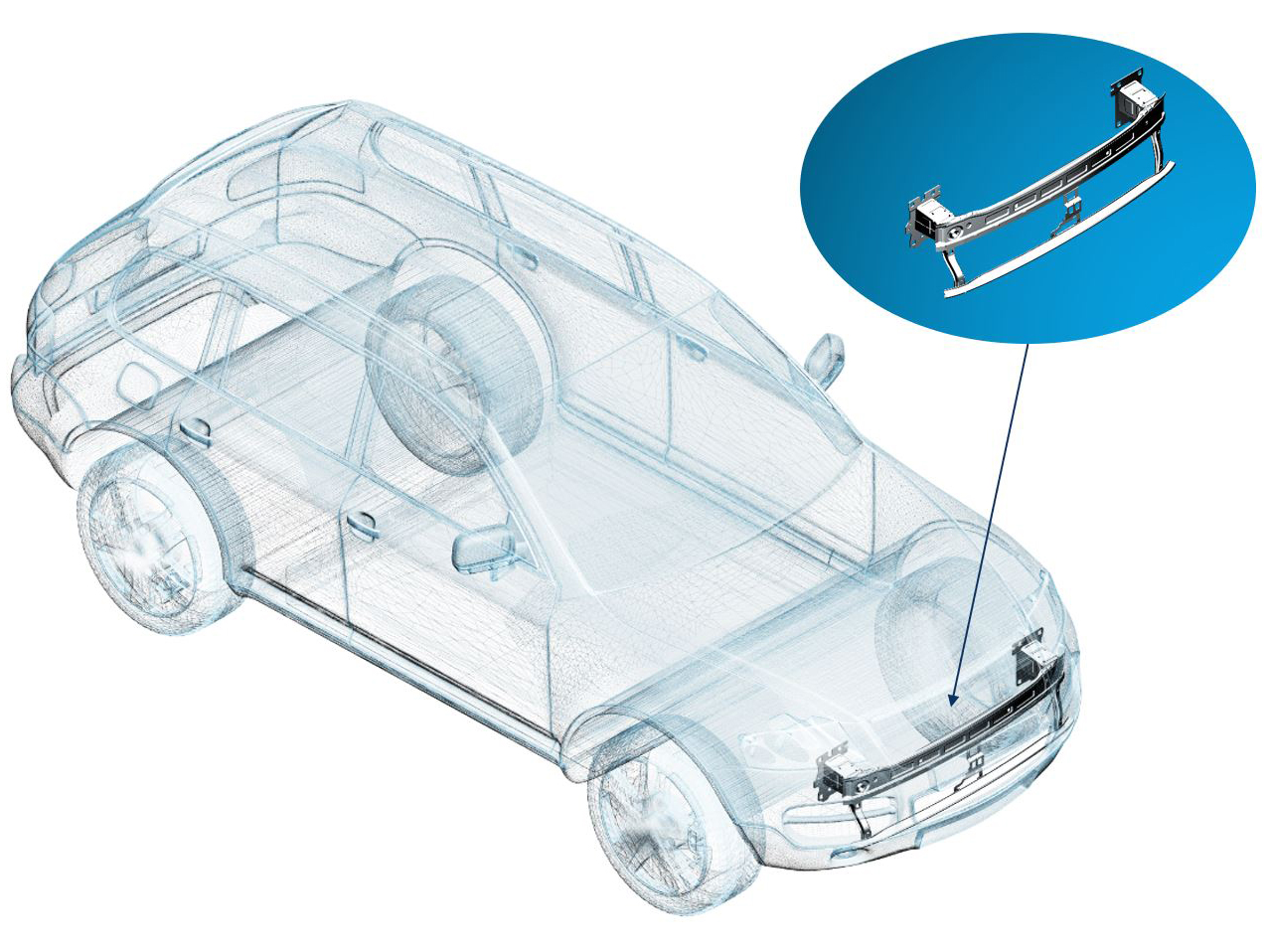

The cost-optimized solution: steel crash management system

With this concept, we can ensure a very high level of passive safety in the future and significantly increase protection against corrosion. Pre-galvanized steels were used for this purpose, whose process-safe processing poses a challenge in particular to the joining technology. In addition to a MAG welding process optimized for galvanized materials, a fully laser-welded concept was realized for the first time. The steel crash management system (CMS) enables continuous energy absorption over long intrusion paths without complete failure.

The lightweight solution: aluminum crash management system

Lightweight solutions are becoming increasingly important, especially for e-vehicles. The crash management system (CMS) we have developed in close cooperation with Hammerer Aluminium Industries (HAI) made of aluminum withstands the strong intrusions that occur in a collision and combines and high structural integrity with lightweight construction. The deformability of this crash management system without significant failure is visible in a simulated crash setup at our booth.

Functional and safe: steel instrument panel beam in open-shell design

With the newly developed instrument panel beam in open shell design, we are expanding our extensive manufacturing portfolio for this product group and creating new design options. Under the right conditions, the new design can be a means of reducing costs. Characteristics of the innovation include a high level of functional integration via the open half-shell, high flexibility in confined spaces and the reduction of weld seams and individual parts.

We will present these new developments and more at our IAA MOBILITY trade fair booth. Here we expect visits from high-ranking representatives of our customers. Our team is particularly looking forward to a visit from German Chancellor Olaf Scholz, who will find out about our innovations as part of his opening tour on September 5.

During the IAA MOBILITY, we will report regularly on our social media channels. Follow us on LinkedIn and Instagram to find our latest news!

31-07-23

The Answer to Growing Demand

Even the Hungarian Minister of Foreign Affairs and Foreign Trade, Péter Szijjártó, was impressed. He recently met with Arndt G. Kirchhoff to announce investment plans in our Hungarian plants.

In new production and logistics halls, we will manufacture body components for the electric car industry. The minister emphasized that this is of crucial importance for the growth of the economy; it is particularly important in the current difficult economic situation to decide where a company develops its capacity.

"A country that can succeed and invest in this new industry can guarantee that its economy will continue to grow in the future," the minister said. He added that KIRCHHOFF Automotive’s investment here is a "sign of confidence in the country and an indication of positive expectations for its future economic development."

Besides Germany and China, Hungary is the only country where all three German premium car brands have production capacities. Hungary is already the fourth largest producer of electric batteries in the world. "Hungary has become the European bastion of this new industry that is emerging before our eyes, and it is impossible to imagine this automotive revolution here in Europe without us," Péter Szijjártó emphasized.

The minister explained that German companies continue to represent, by far, the largest investor community in Hungary: “Around 6,000 German companies employed more than 300,000 people in Hungary, and more and more investments were coming from Germany. This shows that the confidence of German investors in Hungary is stable, it is not affected by political reasons, and that the investment climate remains attractive for German companies."

Bilateral trade between Germany and Hungary has also reached a new record, rising 12 percent last year to more than 60 billion euros. It exceeded 24 billion euros in the first four months of this year, with another record expected by the end of the year.

KIRCHHOFF Automotive is investing around 20 billion HUF (approx. 50 million euros) in new production and logistics halls in Esztergom and Dorog. This will create 80 new jobs. Series production for four customers will start in Dorog in 2024, in a modernized production and logistics hall covering 6,300 m². Two production and logistics halls with a total area of 6,200 m² will be built at the headquarters in Esztergom.

Info: In Hungary, KIRCHHOFF Automotive employs more than 700 people. KIRCHHOFF Automotive has been present here since 2004. At that time, the company began manufacturing body components exclusively for Suzuki. Since then, KIRCHHOFF Automotive has been expanding and can serve around 20 customers with its current capacity. In 2019, the Esztergom site was expanded. Having received orders for larger and more complex assemblies, KIRCHHOFF Automotive has embarked on a completely new expansion phase.

14-07-23

Saving 40% of CO2 with Emission-Free Steel

On the way to a green future, KIRCHHOFF Automotive is strengthening its cooperation with steel supplier SSAB in order to reduce CO2 in car body construction.

Steel is the main component of cold-formed body parts, such as those produced by KIRCHHOFF Automotive. When thinking of the production of this material, one often first thinks of energy-intensive blast furnaces with high CO2 emissions. However, there is another way: using the SSAB Fossil-free Steel TM, we save almost 40% in emissions in the production of a front bumper.

SSAB Fossil-free Steel TM is a steel developed by our raw material supplier SSAB. The steel is produced using a new process that uses DRI (direct-reduced iron) and does not use fossil energy. Instead, biogas and fossil-free electricity are used. The quality and properties of this material are just as good as those of steel conventionally produced by SSAB.

We recently named SSAB Supplier of the Year 2023 in the raw material category. This is the third time the Swedish-Finnish steel company has received the award. "We at SSAB are striving for a close partnership with KIRCHHOFF Automotive. We want to jointly take a leading role in the development and use of CO2 -reduced or CO2 -free steel grades in the automotive sector in the coming years," said and Roman Kaiser (sales director of SSAB Europe) at the award ceremony.

The new steel is used, for example, in the production of a front crash management system. This consists of various individual components such as crash boxes, the main beam, lower beam, and closure plate. The crash boxes, lower beam, and closure plate are produced by cold forming, and the individual parts weigh between 300g and 1.3kg.

The SSAB steel currently used for this crash management system accounts for 40% of its CO2 footprint. By changing SSAB's scope for this bumper to SSAB Fossil-free SteelTM (0.0 CO2e-emissions), its footprint will be reduced by 40%, saving approximately 585,000 kilograms of emissions per year.

“At KIRCHHOFF Automotive, we are taking the reduction of carbon emissions seriously. The partnership with SSAB allows us to further accelerate our efforts in bringing CO2-reduced solutions to our customers and on the road. In addition, it will contribute to the achievement of KIRCHHOFF Automotive’s sustainability targets”, says Michael Rank, executive vice president of procurement.

Info:

SSAB is a Nordic and US-based steel company. It offers value-added products and services developed in close collaboration with its customers to create a stronger, lighter and more sustainable world. SSAB has employees in over 50 countries and has production plants in Sweden, Finland and the USA.

For more information, visit www.ssab.com.

10-07-23

Two Anniversaries, One Success Story

KIRCHHOFF Automotive in Portugal’s plants in Ovar and Cucujães celebrated their 60th anniversary and 30 years of affiliation with KIRCHHOFF Automotive.

Time to celebrate

About 400 employees and 900 family members came to the event with their families to celebrate in summer weather, with good food and accompanied by great music and activities. On the agenda were: speeches by the Kirchhoff family and managing directors, an Excellence Award and jubilee ceremony, a “moment of talent” with a special performance by colleague Eugénio Leite (tooling technician in Ovar) who sang some songs such as the hymn of Ovar, a raffle for five KONECT program gift baskets, and a birthday cake and performance of the Tribal Samba School. On 20 tables, food and drinks were served, prepared, decorated, and managed by our employees from different departments.

"We’re thankful for being here with everyone, for wearing the KA jersey with pride, and above all, enjoying the day. The day is 100% for you!" said managing directors Hugo Ferreira and Armindo Jales.

Arndt G. Kirchhoff, chairman of the advisory board of the KIRCHHOFF Group said, “We are really happy and proud that we can be with you, my brother Wolfgang, our wives, and a big team from Germany that was able to celebrate with you. Thank you all for your day to day effort, attitude, and cooperation. We are really happy that you are here today with your families.“

CEO J. Wolfgang added, "I‘m also really happy to be here with you and really grateful that I could see the great operations that you are running here in Portugal. At the end of the day, you made it happen like a team. We have the latest technologies here in Portugal such as transfer presses, hot forming, and all kinds of latest joining technologies, such as laser welding. You are at the top of the technologies. Even better is how you are running these technologies. So once again, a big, big thank you!“

This success story began in 1963, when there was no automotive industry in Portugal. A group of Portuguese industrialists from the light metal construction sector then decided to set up a company for the production of forming tools and founded Gametal - Metalúrgica da Gandarinha, Lda on June 12, 1963. From the 1970s onwards, the company expanded its product range and also manufactured forming parts for the automotive industry.

The importance of a name

The Portuguese plants have now been part of KIRCHHOFF Automotive for 30 years - but they have only been allowed to call themselves that since 2014. While every new plant has had the word KIRCHHOFF in its name from the very beginning, the Portuguese plants were denied this until 2014. "When the international expansion of the KIRCHHOFF Group began with the acquisition of Gametal - Metalúrgica da Gandarinha, Lda, there was already a Portuguese company called "Kirchhoff Electric Repairs." According to Portuguese law, two companies cannot have the same name," explain Armindo Jales and Hugo Ferreira. "The other company then got into financial difficulties, and after some discussions we were allowed to call ourselves 100% KIRCHHOFF Automotive as of December 19, 2014."

Thanks for many years of employment

The longest-serving employee at the Portuguese plant is Jorge Ribeiro with 20 years. He was specially honored as part of the celebrations. “Congratulations and thank you for all the dedication year after year!” said the managing directors.

More honors

One of the highlights was the Excellence Award 2022 ceremony. The following employees were distinguished: Cristiano Andrade from the tool shop in Cucujães, Joana Araujo from the accounting department in Ovar, José Valente from the metrology department in Ovar, and Rosa Pinho from the welding department in Ovar. "We appreciate the effort, commitment, responsibility, ambition, and particularly, the remarkable dedication to the common goal of all of us – organizational success! We address to the nominated colleagues, their teams, and their leaders, the most sincere congratulations for the distinction received!" said the HR team.

A commemorative publication on the anniversary of the Portuguese sites can be found here: https://www.kirchhoff-automotive.com/de/medien/downloads

04-07-23

Support for Startups in the Circular Economy

Interested startups can apply now until August 11 for a promotion program of the Circular Valley® organization, which supports them in implementing their innovative business ideas and technologies. KIRCHHOFF Automotive is part of an extensive network that supports the startups.

"What Silicon Valley is for digitalization, Circular Valley® is for the circular economy. The goal is to develop concepts for emission control and waste avoidance and recycling," explains Christoph Wagener, Vice President, Research and Product Development, at KIRCHHOFF Automotive.

Following the mission, “Grow the Economy – Protect the Environment”, Circular Valley is looking for startups engaged in the transformation from a linear to a circular economy. In the promotion program, start-ups that successfully apply have the opportunity to come into contact with more than 100 partners, including KIRCHHOFF Automotive, from the Circular Valley® network (industry, research and politics). In addition, the network offers customized expert workshops and training modules through to individual support from numerous coaches.

Here, interested startups can apply or the program.

30-06-23

Award for outstanding quality

As one of only two companies, KIRCHHOFF Automotive has received the award for outstanding quality from Mercedes-Benz. The award ceremony took place as part of the Supplier Circle on June 19, 2023.

Every year, the best suppliers of Mercedes-Benz are being honored in the three categories of quality, innovation and sustainability. This year, KIRCHHOFF Automotive is also among the award winners. For the purchasing area "Production Material", our company received the award for an exceptionally good performance in the area of quality. The appreciation reflects the cooperative partnership between Mercedes-Benz and KIRCHHOFF Automotive.

CEO J. Wolfgang Kirchhoff accepted the award together with Vice President Sales Klaus Lötters and Sales Director Christian Arens on June 19 in Sindelfingen.

"We were very pleased to receive the award and the associated recognition for our achievements over the past years. Numerous colleagues from many different KIRCHHOFF Automotive locations have contributed with their dedication to our achieving this high level of customer satisfaction. The award is also an incentive for us to successfully master future challenges with our customer Mercedes-Benz," said Christian Arens.

J. Wolfgang Kirchhoff added: "This award is both a great honor and an obligation for us to continue supplying our customers with products of the highest quality. A heartfelt thank you to all colleagues in the central divisions and, of course, the production plants, who have made this success possible through teamwork and a high level of personal commitment.”

30-06-23

GM award for consistent quality at volume

Our plant in North York, Canada, has received the GM Supplier Quality Excellence Award. The award is in recognition of our team's outstanding performance.

With the Supplier Quality Excellence Award, GM recognizes the top performing supplier manufacturing locations. These suppliers are required to meet or exceed very strict quality criteria. "You are a critical part of the team who helps ensure our customers are delighted with their product purchase," said Rick Demuynck, Executive Director - GM Global Supplier Quality & Development. "This award is to recognize your performance and thank you for consistently providing quality at volume to our GM manufacturing plants as we continue to navigate through our ever-challenging environment."

On behalf of GM's entire Global Supplier Quality team, he thanked our team for their continued outstanding performance and for "being a valued partner!"

Joshua Forquer, EVP Sales and Technical Development, added, ”The team in North York continue year after year to prioritize our customer and the quality of the products that we ship, first. This sense of community from the team in North York continues to create opportunity for the plant. Recently GM has awarded new business to North York that will go on the new exciting BEV pickup line up! This assembly, along with large BIW assemblies for the ICE version, make North York a key facility supporting GM and their family of trucks.”

Lucian Maduta, Plant Manager in North York, added, “We are very honored to receive this award, a testament to the commitment of our team to achieving excellence. This recognition reinforces our dedication to delivering superior quality and strengthens the partnership we have built with our supplier.”

Picture: Plant Manager Lucian Maduta with the GM Supplier Quality Excellence Award.

23-06-23

An eventful day for the North American purchasing team

June 7th commemorated two very significant events: The Annual North American Procurement Team’s Meeting in Aurora, Ontario, Canada, and the Supplier of the Year awards.

Strategies such as the impact of geopolitical and market trends on respective procurement categories, risk mitigation plans, the CO2 reduction roadmap and sustainability initiatives - were some of the key topics covered at the procurement meeting.

Beyond the technical discussions, the event also included time for team-building activities, including a trip to the bowling alley.

That evening, the Supplier of the Year award was hosted by the North American Procurement Team in Richmond Hill, Ontario, Canada.

Jim Montagano (EVP Operations) opened the ceremony with encouraging sentiments, commenting that “we cannot forget that during the difficult years of COVID-19, we all went through tough times (both personally and in business). Your (suppliers’) support during those tough times was very appreciated, as reflected by the zero shutdowns caused by our supply base during those two years.”

Sumit Dutta (VP Procurement North America) explained the selection criteria of the suppliers of the year: collaboration with stakeholders, service, competitiveness, quality, delivery, and launch support. If a supplier stands out in all of them, they have taken their level from ‘customer satisfaction’ to ‘customer delight’. He clarified that price is not the most important criteria, but it is how the supplier collaborates with various functions during a product’s life cycle. For example: helping win new business, new product development, 24/7 operational support, helping launch new projects on time, and their contribution in meeting the price, quality and delivery objectives. Sumit Dutta explained how each of the suppliers faired in each of above categories, resulting in them being chosen as Suppliers of the Year.

The 2023 Supplier of the Year recipients for each category were:

- Raw Material, Riverview Steel

- Bought In Parts, Canada Tubeform,

- Sub Contracting, Powder Cote II,

- Logistics Buddy’s Upstate Logistics LLC,

- Capital & Tooling, Tri-Tech Fixtures LTD,

- Mexico Excellence Award, Mosmex

- Prototype Services, APhase LL Inc.

Darik Chapman, (Senior Buyer, Raw Material) commented after the event and meetings: “I had such a positive energy on the way home and felt proud to be part of a great team of purchasing professionals. We all have so much potential to do so much for KIRCHHOFF Automotive. I look forward to what is to come and meeting again!”

“The supplier awards event was a showcase of our best suppliers across many different categories. I was pleased to meet and speak with many of them at this event. These were the best of the best and it showed. It was a great event and Sumit and the procurement team did a wonderful job putting it all together. I really enjoyed the evening,” said Mark Fabischek (EVP Global Product Development).

16-06-23

"The Country Will Continue to Grow With You"

On June 14, the Portuguese Prime Minister Dr. António Costa visited our plant in Ovar, Portugal. For our colleagues on site, the visit left a special impression.

At the beginning of his visit, its highlight took place right away - the Prime Minister visited the hot forming line. This had been built in 2019.

For the employees in the hot forming and welding areas, which the Prime Minister then visited, the personal conversation with the politician was a highlight. They explained their tasks to him and how accident-free production with 100% quality is possible.

In showrooms specially set up for the visit, Dr. António Costa learned about various stamped parts and welded products from Ovar and Cucujães, and what kind of technologies are used for them.

During the press conference, the Prime Minister praised the good company organization and structure, the impressive level of technology, and state-of-the-art equipment. He emphasized the strong impact that our industry has on the region. At the same time, he also said that the country needs more companies like KIRCHHOFF Automotive: "If you target to grow 5% per year and exceed that target, we, the country, will continue to grow with you! Your resilience is very important for maintaining jobs, for the growth of exports, and for the country. I would like to thank you, as this is a sign of confidence for the country as a whole. When companies are satisfied with their investment and have the prospect of strengthening their investment, this is a great sign of confidence for our future."

In a good mood and smiling, the Prime Minister left the plant after about an hour. For the employees, it was a special day that left an impression - after all, it's not every day that you have the opportunity to talk to such a high-ranking politician.