15-05-20

The New Normal

The face mask is put on and the hands are freshly disinfected: The workday can begin. This is what everyday life now looks like for many employees. To protect themselves and others from infection with the corona virus, we have introduced new protective measures at our plants. How do our employees deal with them?

Erik Proháska, shift supervisor press shop in Esztergom/Hungary, says: "At first the measures were difficult to get used to, but now the workers take them for granted. What the colleagues liked best was that our company took protective measures such as the use of disinfectants immediately after the outbreak of the virus".

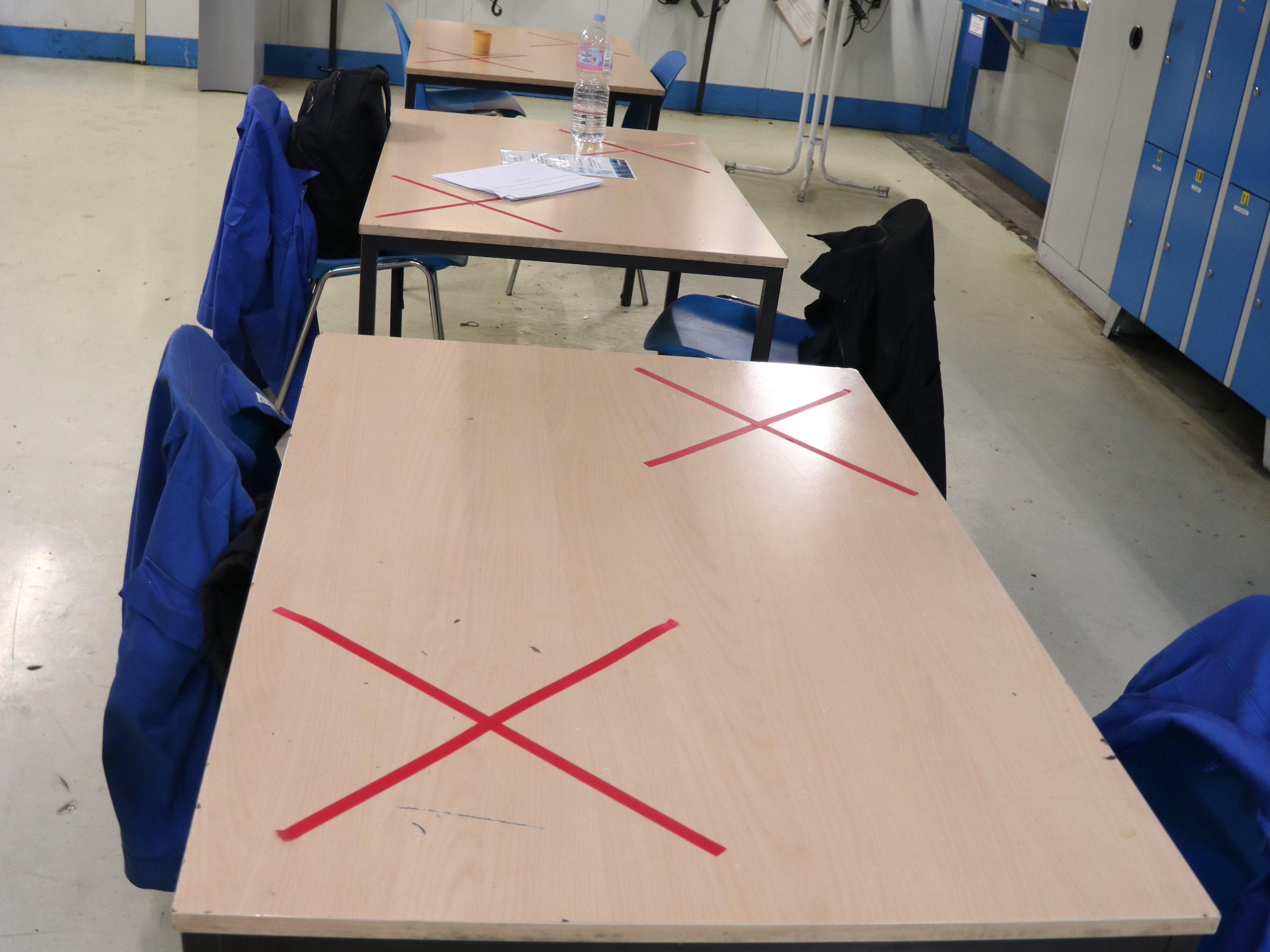

Teams have been partly split up, so that half of them work on site at the plant and the other half in the home office, alternating weekly. Other protective measures include keeping a distance, leaving doors open, regular cleaning of frequently touched surfaces and physical barriers such as Plexiglas walls.

"I have temporarily been in the home office since March," says Sabine Montenbruck, assistant to Production Manager in Iserlohn/Germany. "Working from home works very well. I am grateful that we have this opportunity and that IT was able to equip us with laptops so quickly. At my first meeting in the office, wearing the face mask was still a bit unusual. By the second visit, it was almost routine."

Mike Walsh, Health, Safety & Environmental Manager at Aurora Corporate/Canada, explains: “Corporate and local procurement staff have been working hard to secure purchases of masks, including reusable and disposable masks, hand sanitizer, and cleaning supplies. Each facility has reviewed its inventories and are prepared for return to operations. All employees will be provided with masks should they be required to use them where we cannot provide sufficient physical distancing for the tasks they perform, government mandated, or in case employees want to wear voluntarily.”

"Some employees still have difficulty maintaining the necessary safety distance, especially at the gatehouses and the time clocks," says Fábio Valente, Health and Safety Technician in Ovar/ Portugal. Proof of disinfection of the workplaces before each shift or machine use is also a challenge, he says. In general, however, the protective measures are well accepted by the employees. "To prevent the spread of Covid-19 in our company, everyone must show responsibility. That's the message we must send to everyone."

Hugo Ferreira, Global Director KAPS in Ovar/Portugal, still works from home. "For my department, the biggest challenge is that we are not allowed to travel and hold workshops on site. That's why we do them online. Otherwise, the changeover is not dramatic for us. We are used to working in different places. So we had already established management systems to coordinate our teams."

"Wearing the masks, disinfecting hands and surfaces became very easy habits. Sometimes we forget to take off the masks, for example when we drink a glass of water or just eat a snack - they have already become a part of us," says Corina Mandă, Management Assistant in Craiova/Romania.

Thomas Lozinski, Head of Hot Forming & Trailer Systems at the Iserlohn/Germany plant is optimistic: "We don't let our work spoil the fun and make the best of the situation. We know that KIRCHHOFF Automotive is well positioned and that we will survive this difficult time. You can feel the fighting spirit in the workforce and the willingness to help overcome the crisis. The community and cohesion in the company are important pillars for all employees and provide security.

We all have to get used to this new normal. In order to protect ourselves and others, the measures will probably remain in place for quite some time. But we are confident that by doing so, we can all contribute to the safe working conditions in our factories.