Forming

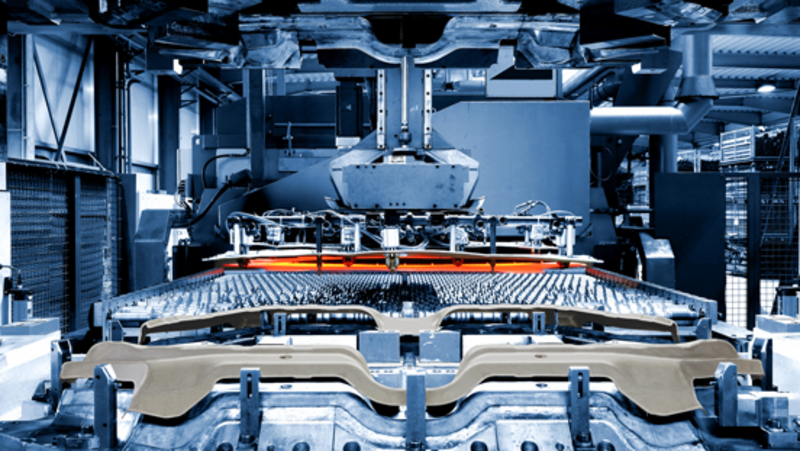

Forming represents the beginning of our production chain. On modern Servo and Transfer Presses, with press capacities up to 2,500 tons, we produce complex metal parts with thicknesses from 0,6 mm to 12 mm. In doing so, we use all modern steel and aluminum materials.

By use of most modern hot forming production lines we are able to manufacture products with strengths up to 2,000 MPa. By partial press hardening, we offer our customers the production of parts with different strength regions. Therefore we fulfill the crash relevant requirements in the area of the passenger cab.

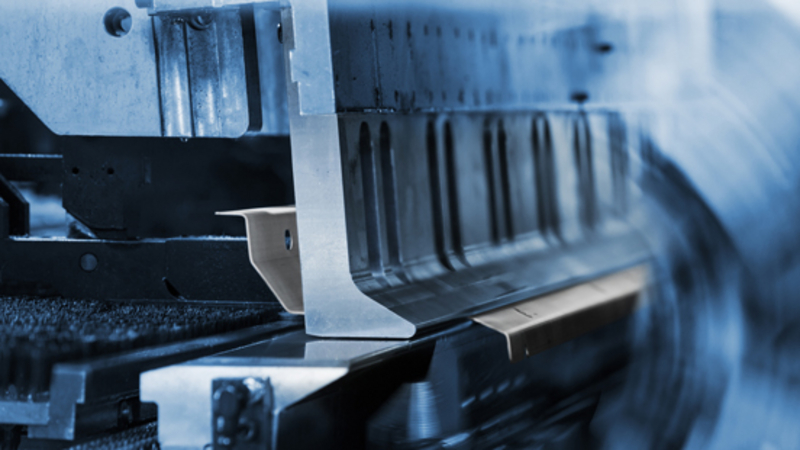

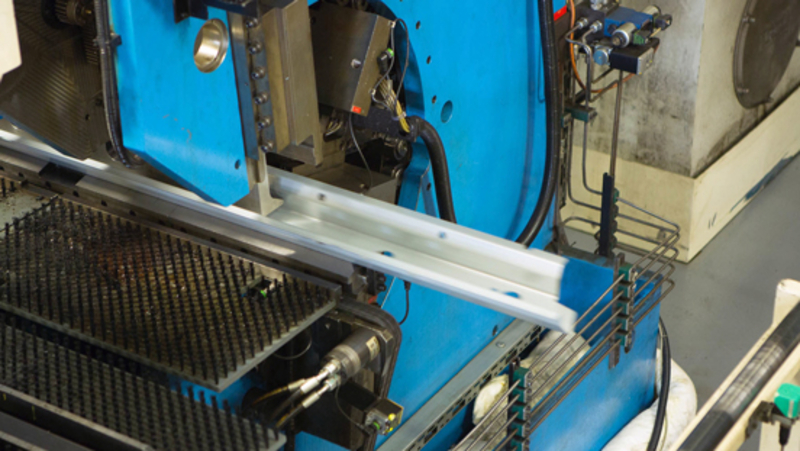

CNC wing bending is used to produce profiles for modern body structures.

This process allows high dimensional accuracy with small tolerances for open and closed section profiles out of ultra-high strength martensitic steel (up to 1,500 MPa). Benefits include low tooling costs and optimal utilization of material by use of standard tooling for different profiles. Compared to roll forming, different stamping and bending operations – depending on the part - can be integrated into the machining. This allows the part to leave the wing bending equipment without the need for additional processes. By use of the CNC wing bending benefits we are able to develop complete assemblies that offer particularly profitable lightweight and structurally rigid solutions.